Functional heat sealant Dynaleo™ PR/CT Series

Characteristics

- Excellent adhesion to various base materials (metals, polar base materials, etc.)

- Excellent heat and humidity resistance, weather resistance, and moldability

- Coloring and curing temperature can be changed according to your request.

Lineup

In addition to regular products, we also have a lineup adhesives that can be bonded at low temperatures.

- Highly durable and weather resistant Dynaleo™ PR series

- High heat resistance and high molding Dynaleo™ CT series

| Product name | Heat seal temperature | Heat resistance | Weatherability | Moldability |

|---|---|---|---|---|

| Dynaleo™ PR series | 170℃ | ◎ | ◎ | × |

| Dynaleo™ PR series (low temperature adhesive type) | 100℃~120℃ | |||

| Dynaleo™ CT series | 190℃ | ◎ | × | ◎ |

| Dynaleo™ CT series (low temperature adhesive type) | 100℃~120℃ | |||

| Conventional heat seal | 120℃~160℃ | △ | × | × |

Product physical properties

Highly durable and weather resistant Dynaleo™ PR series

- Heat seal adhesives with excellent durability (humid heat resistance, weather resistance) that does not deteriorate even in harsh environments exposed to sunlight, wind and rain

- We also have a track record in solar cell backsheet.

Weather resistant coating agent Dynaleo™ PRC/DPT series

| Humid heat resistance | Adhesive strength maintained after 1000 hours at 85℃ and 85%RH |

|---|---|

| Weatherability | After S-Xe 1000h ΔE<2 |

| Adhesive performance *1 | PET | NY | AL | PC |

|---|---|---|---|---|

| Base material adhesion *2 Crosscut test, number of remaining squares/100 squares |

100 | 100 | 95 | 100 |

*1: Uses Dynaleo PRC-002 (general grade)

*2: 3g/m2 (dry) coating and drying at 100℃ for 1 minute

High heat resistance and high moldability Dynaleo™ CT series

- Heat seal adhesives with excellent adhesion between film and metal

- Processing and molding possible after lamination

| Humid heat resistance | 125℃/30min.No peeling or whitening |

|---|---|

| Appropriate for coating | Prevents wrinkles and unevenness even when coating at 150m/min. |

| Adhesive performance *1 | PET | NY | AL | PC |

|---|---|---|---|---|

| Base material adhesion *2 Crosscut test, number of remaining squares/100 squares |

100 | 100 | 100 | 100 |

| Peel strength *3 90° peeling, N/10mm |

Base material rupture |

Base material rupture |

2.5 | 1.0 |

*1: Using Dynaleo CT-001 (general grade)

*2: 3g/m2 (dry) coating and drying at 100℃ for 1 minute

*3: 3g/m2 (dry) coating, drying at 100℃ for 1 minute, heat lamination (190℃, 1m/min., 0.5MPa, aging at 150℃ for 20 minutes)

No lifting of adhesive layer even when molded after heat curing

Immediately after Rami

Aperture height 6mm

Aperture height 14mm

Example of use

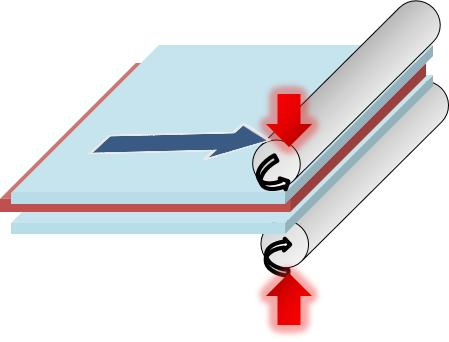

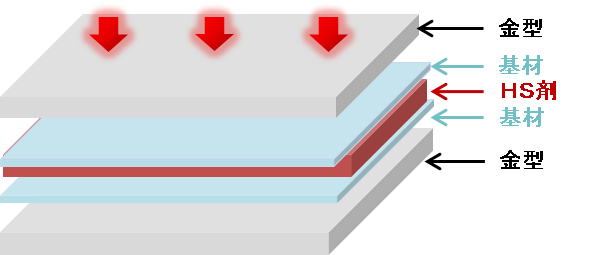

By applying heat and pressure to a film coated with a functional heat seal adhesives, it is possible to bond different types.

- heated roll press

- heat press molding

Application examples: Automotive interior parts, solar cell related parts, building materials processing, etc.

Inquiries

TOYOCHEM CO., LTD. Packaging and Industrial Materials Sales Division Sales Department 1

TEL:+81-3-3272-0940