Integrated Report 2025Strengths of the artience Group: Business Development Based on Unique Core Technology

Published on June 27, 2025

This page has been translated using AI.

Moving forward with next-generation development with customers, leveraging proprietary dispersion technologies

Conductive CNT Dispersions Business for Lithium-ion Battery Cathode Materials

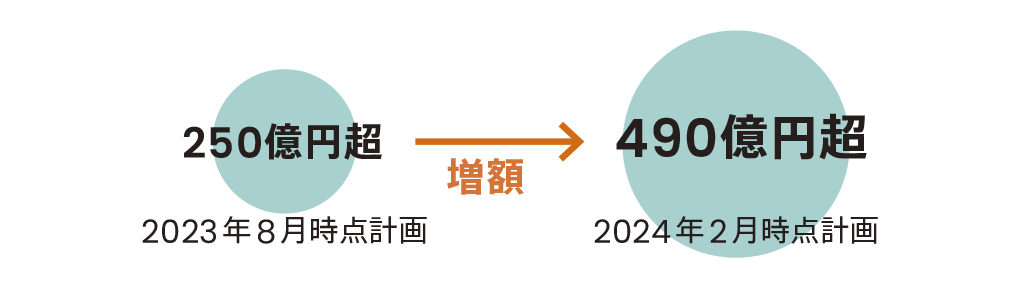

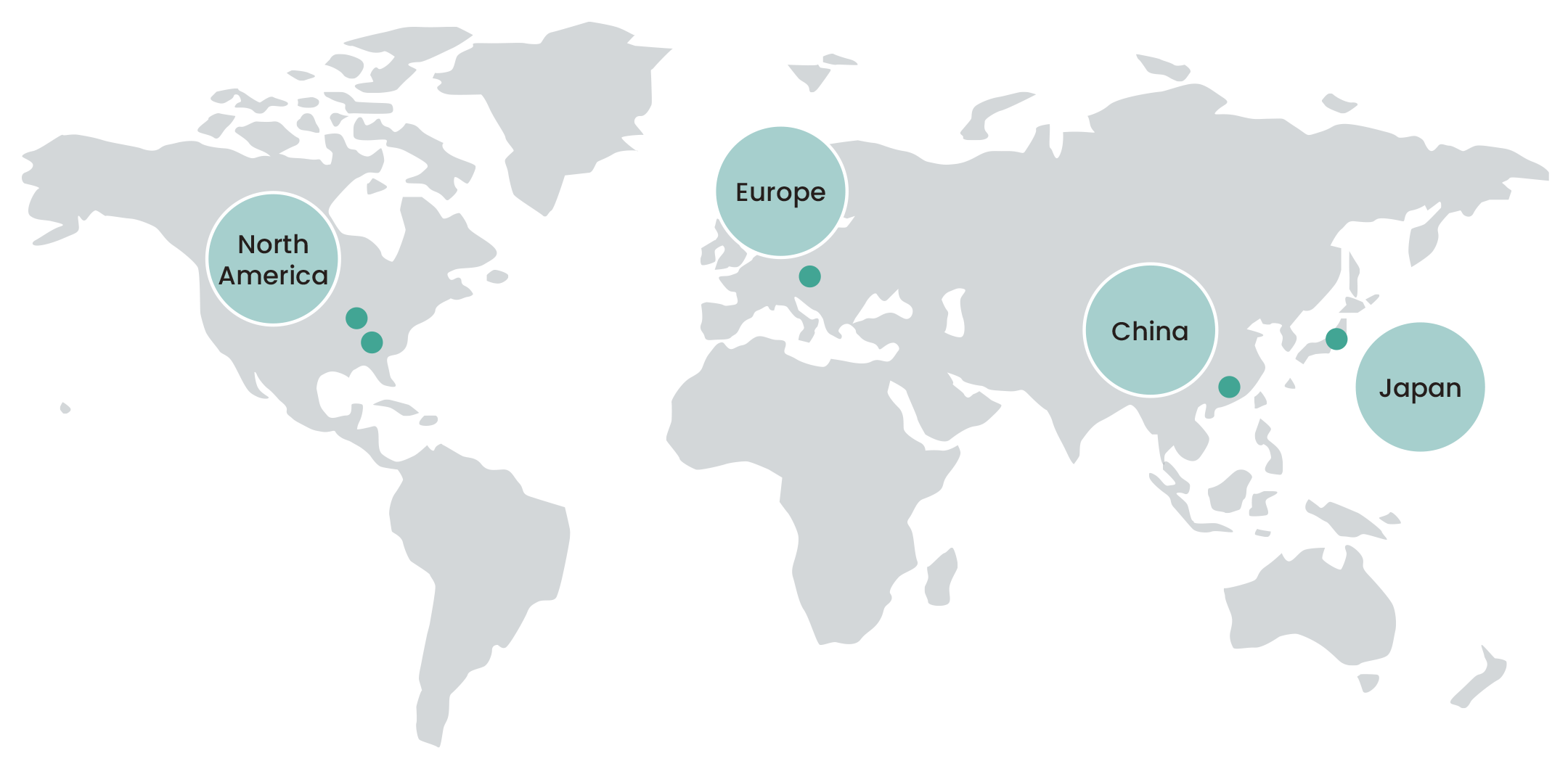

Conductive carbon nanotube (CNT) dispersions for cathode materials support high capacity and high output for lithium-ion batteries (LiBs,) which are essential for electric vehicles (EVs.) The artience Group has positioned CNT dispersions as a strategic priority business, and is accelerating efforts to secure new customers and develop new technologies by establishing a production system, with five bases in four regions in Japan and overseas.

Koji Obata

Market environment

With countries around the world tightening their environmental regulations to reduce CO2 emissions, the automotive industry is leaning heavily toward electrification. The artience Group has been actively engaged in the CNT dispersion business since 2019, supplying CNT dispersions for EV LiB electrodes. Because CNT offers higher conductivity than carbon black, a widely used conductive additive for LiBs, CNT has been attracting attention as a material that can contribute to the production of high-capacity, high-output, long-lasting LiBs. This is significant because the capacity, output, and service life of LiBs can affect the driving range and charging performance of EVs.

FY2024 was a challenging year for the EV market as a whole, with policy changes in various countries, inflation, and rising interest rates all contributing to slower growth. Shipments to major existing customers in the US were sluggish. While sales of EVs and plug-in hybrid vehicles in China grew significantly year on year, sales of Japanese and European brands were sluggish, and orders from LiB manufacturers that primarily handle European vehicles remained flat.

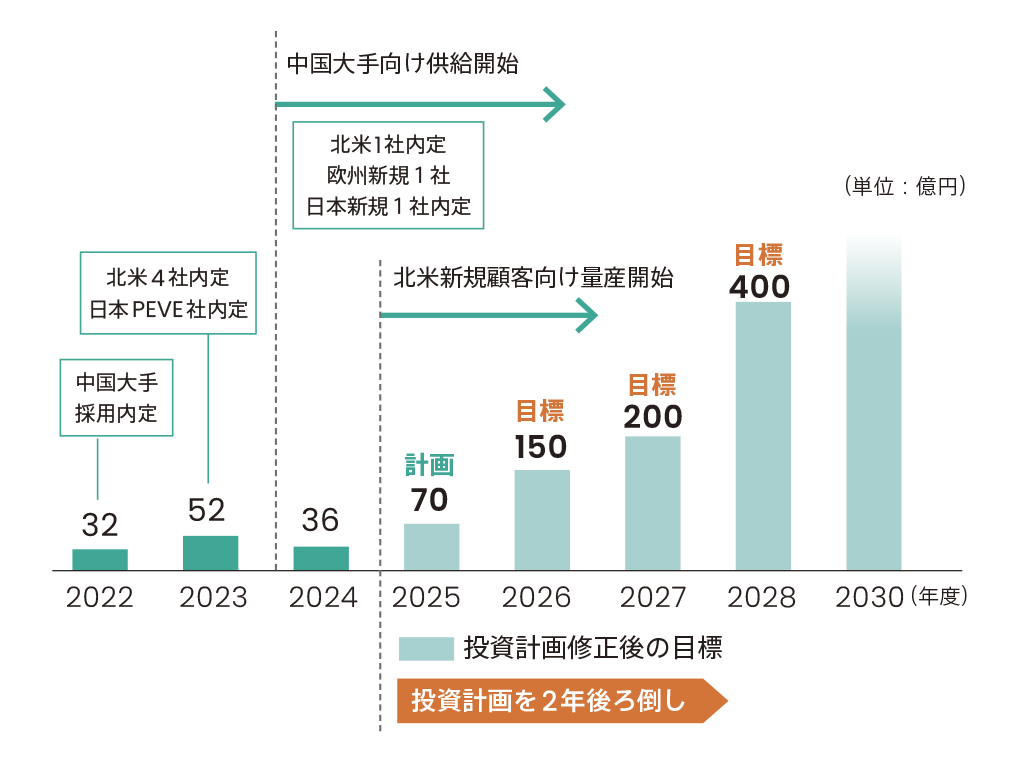

Changes in sales of the business and forecast / target (as on November 2024)

Progress

In light of these circumstances, we have decided to postpone the net sales and market share targets set under our artience2027, Medium-term Management Plan by two years.

Meanwhile, full-scale production is now underway in Zhuhai, China, and progress has also been made in expanding production capacity for mass production at our bases in Kentucky, USA, and Hungary. In addition, the number of customers who have informally decided to adopt our products has grown from seven in 2023 to ten in 2024. Although we are experiencing temporary market stagnation, the medium- to long-term growth trend remains unchanged, and we will continue to strengthen our efforts in this area as a strategic priority.

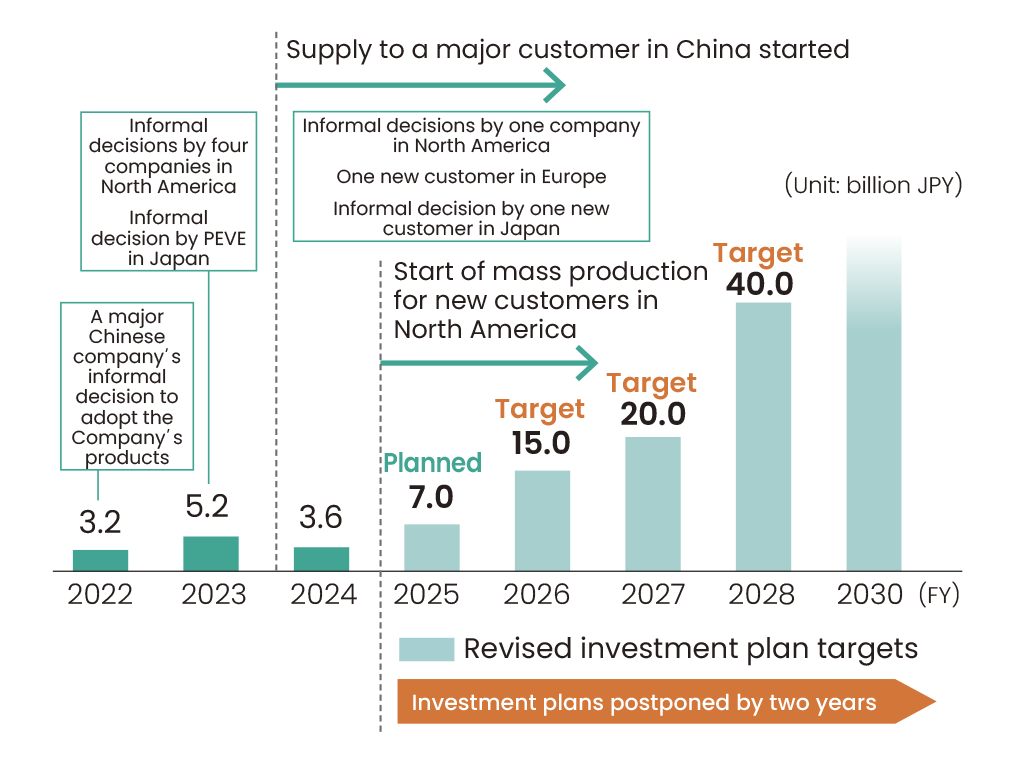

Total investment planned in this business (FY2019—)

Competitive advantage

Our CNT dispersions for LiBs originated from the dispersion technologies used to uniformly mix pigments in printing inks. Using core technologies accumulated over the course of more than 100 years, we carefully separate CNTs one by one without damaging them, then disperse them at the nano level to maximize their electrical conductivity. We have also developed our own dispersion agents and improved them over time. Another one of our key strengths is our customizable production process. For example, we can control the length of CNT fibers to meet customer requirements.

In addition, CNT dispersions are used in automotive LiBs, so quality requirements are strict. Based on thorough consultations with our customers, we design products that ensure safety, and carry out daily production activities under a strict quality control system. Our automotive LiBs have been commercially available for use in hybrid vehicle (HV) applications for over ten years, and we believe that they have earned a reputation for reliability in the market.

In our main markets (Europe, the US, China, and Japan,) we have established a supply system that enables stable localized procurement and production, and have built strong trust and networks with our customers based on our results. In the current unstable political climate, having a system that can quickly supply products locally is a significant advantage. We are also building a global patent network to deter new competitors from entering the market, which we believe will give us a competitive advantage.

- Dispersion technologies that maximize CNT performance

- Strict quality control system

- Mass production system with five bases in four regions

We have set the target of securing a 20% share of the global market for CNT dispersions for LiBs (as a percentage of total demand for automotive LiB capacity) by FY2032, and will stay ahead of the diversification of EVs and the corresponding changes in LiBs. In addition to our existing conductive additives for ternary systems, which are designed for high capacity and performance, we are also considering products that address cost-conscious needs, such as low-cost lithium iron phosphate (LFP) batteries. At the same time, it is important to build a development system that can respond to diverse needs while maintaining awareness of next-generation, high-end products, such as all-solid-state batteries.

Expanding our customer base is essential for business growth. As our customer base grows, we will be able to gather more information, which will allow us to understand market trends more accurately and incorporate them into our business strategy. In addition, building a solid track record of business results will make it easier to expand and cater to new customers.

We will continue to invest actively in increasing our supply capacity, while constantly reviewing and optimizing the timing and amount of our investments. A long-term perspective is essential in this business because the process from investment decision to equipment installation and start of mass production takes between two and two-and-a-half years. We will incorporate market needs into our business plans and take the necessary actions based on close sharing of information with customers and component manufacturers.

Long-term vision for the future

The trend toward achieving carbon neutrality is growing stronger, and we believe that social demand for EVs will remain high in the future. While it is necessary to carefully monitor power generation methods for charging and CO2 emissions throughout LiB life cycles, the fact remains that electrification is an essential element for the automotive industry as it moves toward decarbonization. Our focus should be on contributing to the improvement of price, driving range, and charging times — key issues hindering the widespread adoption of EVs — through the provision of CNT dispersions for LiBs. We believe that encouraging consumers to choose EVs and contributing to the realization of carbon neutrality in this way will also help us to achieve one of the artience Group’s material issues: providing value that resonates with the senses through our products and services.

Materials for lithium-ion batteries