Business/Products

Toyo Ink SC Holdings Co., Ltd.

Developed sintered silver nanobonding material for power electronics

~ Contributing to cost reduction in the power semiconductor manufacturing process with an innovative bonding material that combines pressure-free and high heat dissipation ~

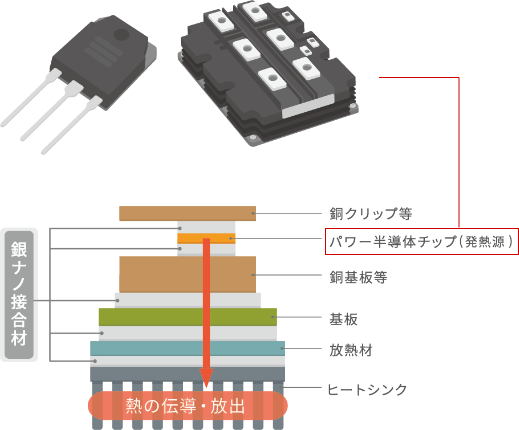

TOYO INK SC Holdings Corporation (President and Representative Director Satoru Takashima, Chuo-ku, Tokyo) has developed a sintered silver nano-junction material that combines sintering without pressure and high heat dissipation for use in electronics products such as power semiconductor chips.

With the expansion of electric vehicles, the demand for semiconductors is expanding, and in particular, the adoption of SiC semiconductors, which have less energy loss when regulating current and voltage, is progressing. On the other hand, SiC semiconductors have higher operating temperatures than conventional Si semiconductors, and higher heat resistance and heat dissipation characteristics are required, so there is a need for bonding materials to replace conventional lead-free solders.

The sintered silver nanobonding material developed by TOYO INK SC Holdings is an unprecedented bonding material for power semiconductors that achieves both pressureless sintering and high heat dissipation. This product can be directly bonded to a copper base plate, exhibits a thermal conductivity of 300 W/mk or more, a bonding strength of 40 MPa or more, * 1, and can be used for thin-film chips and specially-shaped chips.

Existing equipment such as solder reflow ovens can also be used, and a large number of chips can be sintered at the same time, and sintering can be done in a shorter time of 5~30 minutes than conventional products, contributing not only to capital investment costs but also to reducing time and energy in the power semiconductor manufacturing process. This product is suitable for joining inverter modules for automotive and electric railways, automotive ECUs, high-frequency devices, power ICs, and high-power LEDs that require high heat dissipation. In addition to the non-pressurized type, we also have a lineup of pressurized types that can suppress damage to chips and substrates by joining them uniformly and at low pressure.

Power semiconductors with high power efficiency are one of the key materials for the realization of a decarbonized society. The Toyo Ink Group will contribute to the realization of a sustainable society by solving social issues through the provision of products and services born from its unique technologies.

Please see our website for more details.

https://schd.toyoinkgroup.com/ja/rd/casestudy/silvernano.html

1 Measurement limit value using our evaluation equipment

2 TOYO INK and the TOYO INK logo are registered trademarks of Toyo INK SC Holdings Co., Ltd.

###

Inquiries

TOYO INK SC Holdings Co., Ltd.

Corporate Communication Department

MAIL: info@toyoinkgroup.com