Business/Products

TOYOCOLOR CO., LTD.

Toyocolor conductive CNT dispersions adopted for Toyota hybrid vehicles

This page has been translated using AI.

February 6, 2024, Tokyo, Japan—Toyocolor Co., Ltd., the colorants and functional materials division of the artience group (formerly Toyo Ink Group of Japan), announced today that its LIOACCUM™ conductive carbon nanotubes (CNT) dispersions manufactured have been adopted as a conductive additive for use in lithium-ion batteries (LiBs) produced by Primearth EV Energy Co., Ltd. (PEVE). PEVE is an automotive battery manufacturer established in 1996 as a joint venture between Toyota Motor Corporation and Matsushita Electric Industrial Co., Ltd. (now Panasonic Holdings).

Shipments of PEVE’s LiBs containing LIOACCUM dispersions have started in Japan for installation in hybrid vehicles manufactured by Toyota Motor Corporation. In conjunction with this development, Toyocolor is expanding its dispersions production base at its Fuji Plant in Fuji City (Shizuoka Prefecture, Japan) to bolster its production capacity.

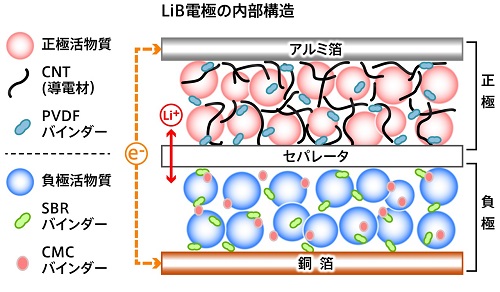

Features of the CNT dispersions LIOACCUM ™ for lithium-ion battery cathode materials

Higher conductivity CNT for higher capacity, output

Toyocolor has been supplying carbon dispersions for LiB cathode materials since 2015, building a solid track record as a battery material manufacturer.

LiB cathodes are mainly composed of an active material, a conductive additive and a binder. Toyocolor, by applying its proprietary additives and dispersion manufacturing methods, was able to replace carbon black with CNT as the conductive additive, needing only a small amount of the additive to realize conductive performance. This breakthrough dramatically reduced the resistance value of lithium-ion battery cathodes, while significantly increasing CNT dispersibility and conductivity.

Less additive usage not only translates into reduced material costs for battery manufacturers, but it also means more cathode cell space to insert active material. This in turn helps to extend the cruising range of hybrid vehicles, plug-in hybrid vehicles, and electric vehicles, while improving charging speeds.

Related Pages

Materials for lithium-ion batteries

About Primearth EV Energy Co., Ltd.

Primearth EV Energy Co., Ltd. is an automotive battery manufacturer established in 1996 as a joint venture between Toyota Motor Corporation and Matsushita Electric Industrial Co., Ltd. (now Panasonic Holdings). For more information about Primearth EV Energy Co., Ltd., please visit the following website.

###

Inquiries

TOYOCOLOR CO., LTD.

Functional Materials Sales Department

Person in charge: Usui

TEL: +81-3-3272-0956

Press inquiries

artience Co., Ltd.

Corporate Communication Department

TEL: +81-3-3272-5720

MAIL: info@artiencegroup.com