Packaging paper solution

Packaging can be made more of paper

artience group proposes solutions that expand the possibilities of converting film packages into paper.

- Issues with paper conversion

- Solutions Proposed by the artience group

- Towards the realization of paper packaging

Issues in converting film packaging to paper

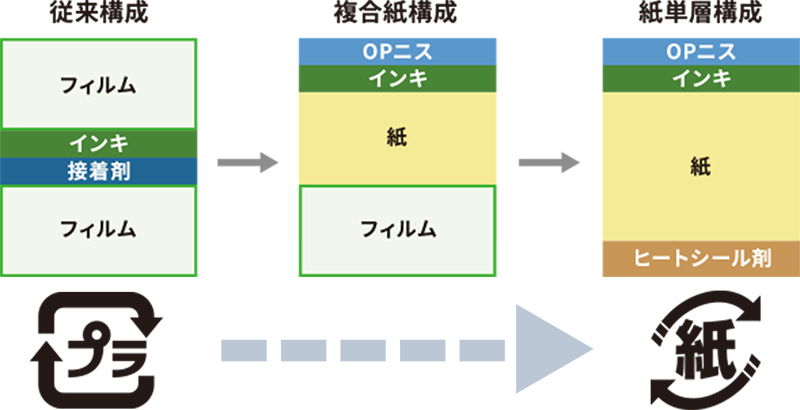

The advent of single-layer paper packaging and paper/film composite packaging has increased their environmental contribution, but on the other hand, the following issues have been raised regarding their performance and manufacturing processes.

Comparison with conventional configuration

| Structure | Composition and distribution | environment Degree of contribution |

of the package Strength/durability |

Contents protection |

item ink Peeling off |

packaging machinery Compatibility with |

|---|---|---|---|---|---|---|

| Conventional configuration | Film laminate configuration Currently, it is widely distributed in food packaging. |

|

|

|

|

|

| Composite paper composition | Composite composition of paper and film Already on the market in primary and secondary packaging |

|

|

|

|

|

| Paper single layer composition | Paper single layer structure Already on the market in secondary packaging, but usage is limited |

|

|

|

|

|

Solutions Proposed by the artience group

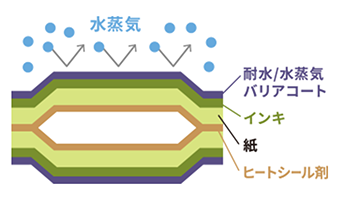

We solve problems with paper single-layer structures using a wide range of lineups and material technologies.

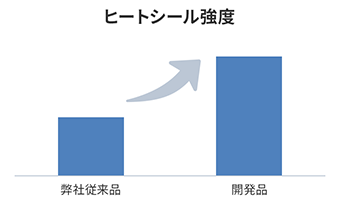

Improve package strength and durability with heat sealant

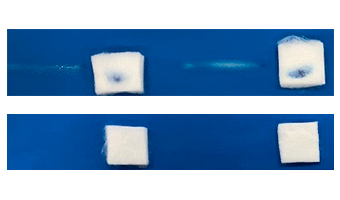

Protect contents with barrier coating agent

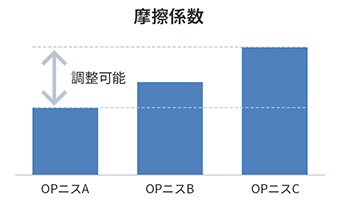

Protect the printed surface with OP varnish and prevent ink from peeling off.

Bag making and filling processing can be done using conventional packaging machines.

Paper single layer structure proposed by artience group

| Structure | Composition and distribution | environment Degree of contribution |

of the package Strength/durability |

Contents protection |

item ink Peeling off |

packaging machinery Compatibility with |

|---|---|---|---|---|---|---|

| Conventional configuration | Film laminate configuration Currently, it is widely distributed in food packaging. |

|

|

|

|

|

| Composite paper composition | Composite composition of paper and film Already on the market in primary and secondary packaging |

|

|

|

|

|

| Paper single layer composition | Paper single layer structure Already on the market in secondary packaging, but usage is limited |

|

|

|

|

|

| Suggestion Paper single layer structure |

Single layer paper structure (using our coating agent) Possible to expand secondary packaging applications and develop into primary packaging |

|

|

|

|

|

Towards the realization of paper packaging

Coating agents such as heat sealants and OP varnishes proposed by artience group solve four problems in packaging paper and expand the possibilities of single-layer paper structures. This will significantly reduce the amount of plastic used and promote environmentally friendly packaging.

Packaging can be made more of paper.

artience group will create the future of your paper packaging.

Inquiries

TOYO INK CO., LTD.