Application technology of “color material design” Optical control

Technology overview

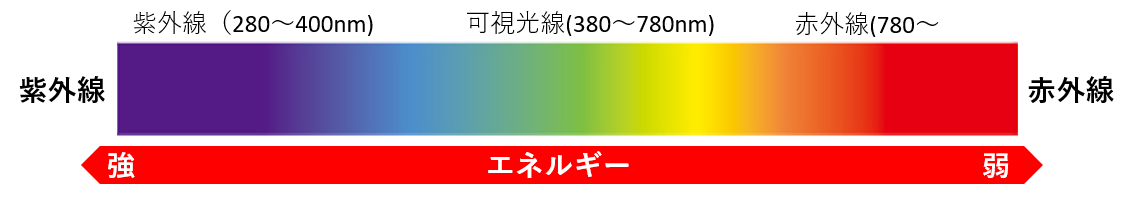

In order to reproduce colors with high color rendering and improve visibility on display devices such as televisions and smartphones, it is important to control the transmission, absorption, reflection, and scattering of light in materials.

wavelength control

Technology that selectively uses only the necessary wavelengths is essential for controlling the efficiency of light energy use and improving the sensitivity of optical sensors. By combining unique materials that absorb certain wavelengths, our group is able to selectively transmit or block the desired wavelength range.

refractive index control

Light is reflected and refracted at interfaces with different refractive indexes. Controlling the direction in which light travels is important for improving light extraction efficiency in lighting and preventing reflections on displays. Our group selects fine particles with different refractive indexes and finely disperses them down to tens of nanometers using our proprietary resin material, making it possible to provide paints and coatings with the desired refractive index.

Product Case Studies

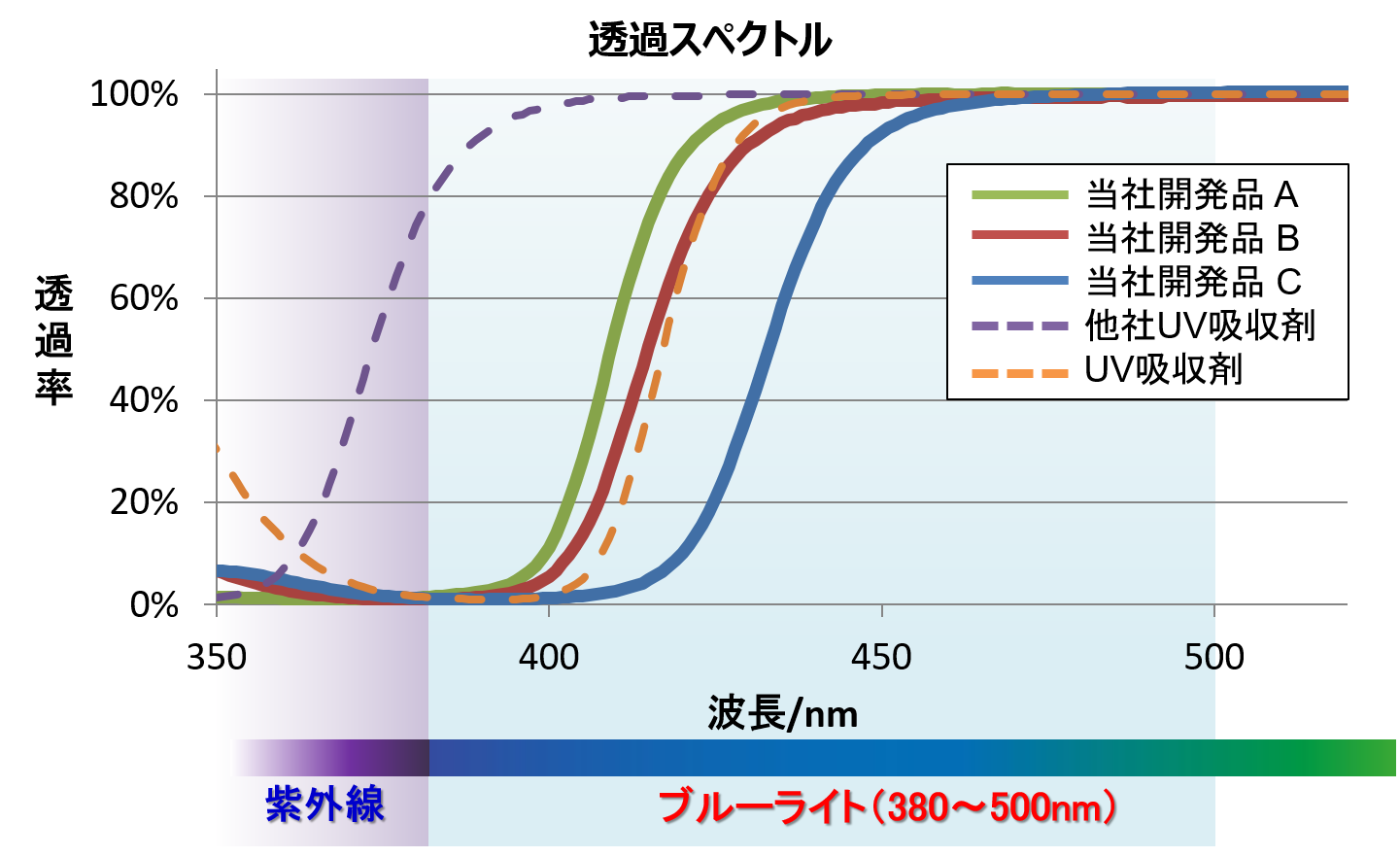

Highly resistant blue light cut agent

Highly resistant blue light cut agent

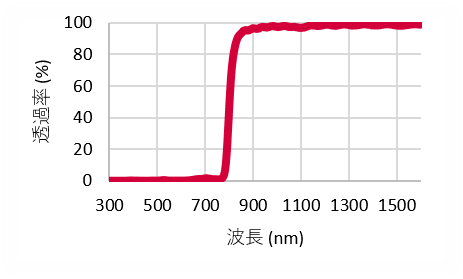

Near-infrared transmissive materials

Near-infrared transmissive materials

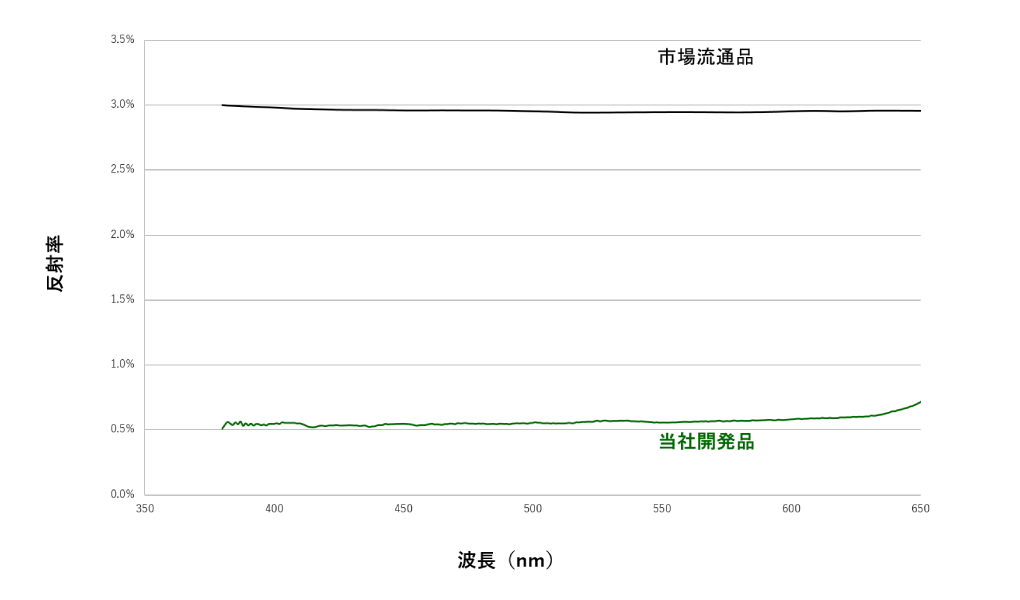

low reflective black ink

For various optical cameras/sensors, it is important to accurately deliver the necessary signals. Our group's low-reflection black ink has overwhelmingly low reflectivity (0.5% or less) compared to general products. This low reflection performance allows you to control excess signals within the camera/sensor.

Wavelength of low reflective black ink

Comparison of low reflective black ink