Highly resistant blue light cut agent

It is expected to extend the lifespan of organic EL displays, and it will also be possible to deploy it in automotive applications and outdoor signage, which require durability in harsher usage environments.

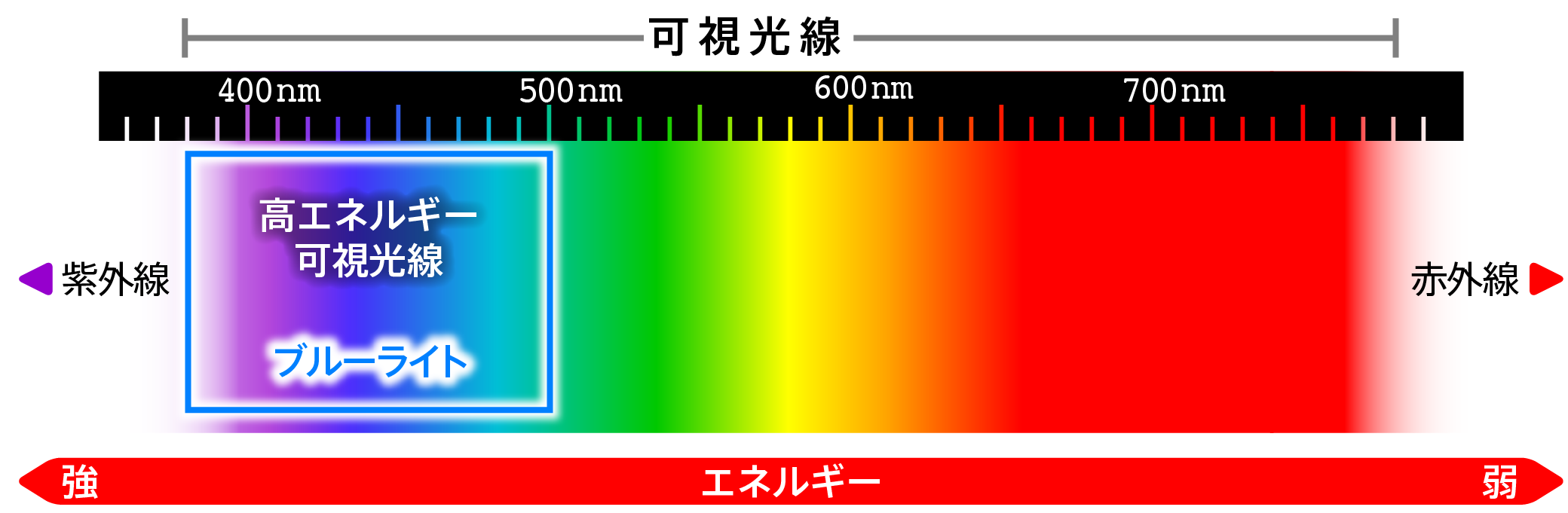

What is blue light?

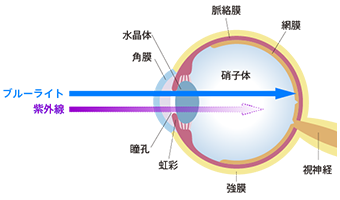

Blue light (high-energy visible light) has a wavelength (380 nm to 500 nm) that is close to ultraviolet light among visible light rays, and is a very strong energy light. Blue light has various effects on the human body, materials, and contents.

Effects of blue light

Impact on materials/contents

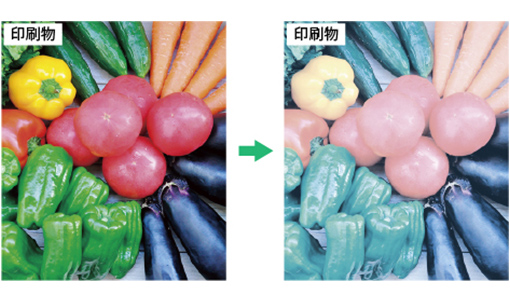

The ultraviolet rays contained in sunlight have the property of deteriorating materials, and as shown in the example above, materials deteriorate over time.

However, in fact, not only ultraviolet rays but also blue light have the ability to degrade materials.

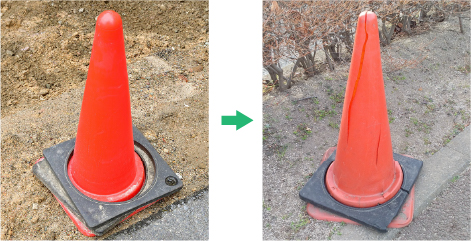

The diagram below compares the protective ability of materials (substances): 1) No protection layer, 2) UV protection layer only, and 3) UV protection layer + blue light protection layer. By blocking both ultraviolet rays and blue light, you can expect an even greater effect in preventing the deterioration of organic matter.

Cases where ultraviolet rays and blue light contained in sunlight degrade materials

Deterioration of printed matter over time

Deterioration over time of colored cones placed outdoors

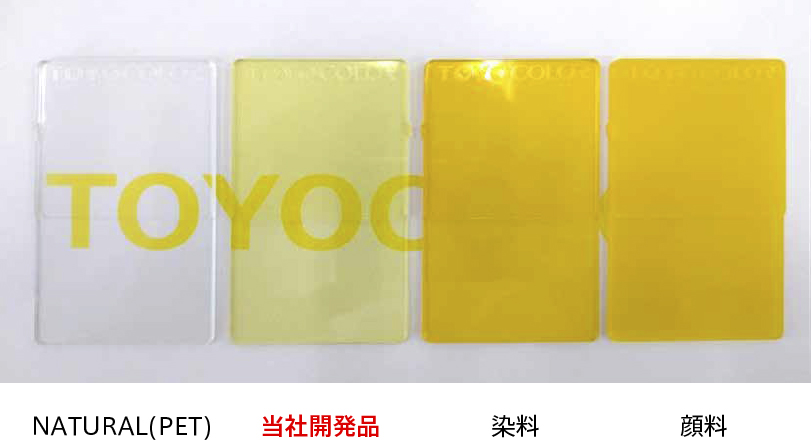

An example of material protection by cutting blue light: Yellow pigments

Effect on the human body

It has also been reported that exposing your eyes to blue light for a long period of time can cause flickering in your vision and eye fatigue, as well as disrupt your internal rhythm and cause sleep disorders.

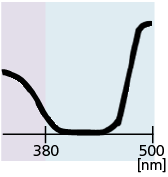

Main materials that cut blue light

There are various materials that cut blue light, and each material has its advantages and disadvantages.

Our developed products demonstrate a high level of performance in a variety of ways.

| transmission spectrum | Light Fastness | Heat resistance | transparency | Required amount added (cutting of blue light area) |

|

|---|---|---|---|---|---|

| Products developed by our company |  |

〇 | 〇 | 〇 | 〇 |

| UV absorber |  |

〇 | 〇 | 〇 | × |

| long wavelength UV absorber |  |

× | × | 〇 | 〇 |

| yellow dye |  |

× | × | 〇 | 〇 |

| yellow pigments |  |

〇 | △ | × | △ |

Product features

Can effectively cut blue light

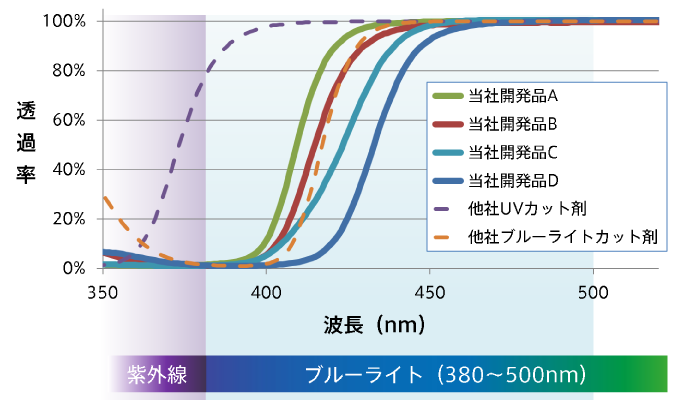

High light and heat resistance

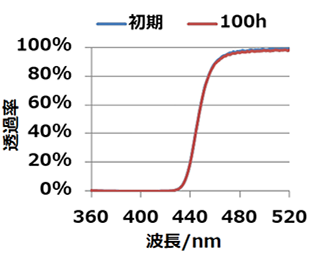

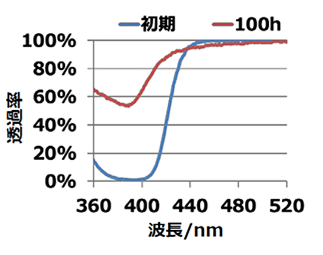

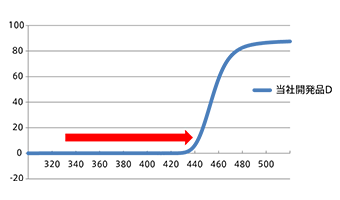

Change in transmittance after 100 hours of xenon lamp irradiation

The product developed by our company has higher light resistance and heat resistance than other companies' long wavelength UV absorbers.

Our developed product B

Our developed product D

Other wavelength UV absorbers

Thermal decomposition start temperature

| Our developed product A | Our developed product B | Our developed product C | Our developed product D | |

|---|---|---|---|---|

| T.D. (TG-DTA) |

320℃ | 280℃ | 320℃ | 350℃ |

Effects that can be expected for each application

Display/optical device

Display: OCA, cover film, optical film, etc.

Optical devices: VR/AR glasses, optical lenses, optical filters, etc.

Effect: Cuts blue light with high efficiency and can protect optical components.

By using our developed product, you can expect to cut blue light with high efficiency and protect optical components.

It can also be used for the following purposes.

- It has high light resistance and heat resistance, and can be used outdoors and in applications that require high-temperature processing.

- It can be used not only for protection purposes, but also for purposes where you want to control wavelengths in the ultraviolet and blue light cut regions.

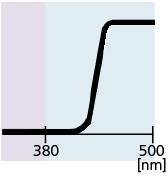

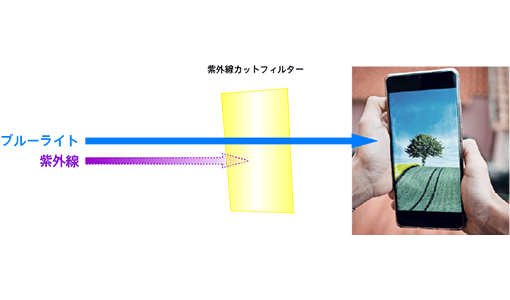

Image of protecting optical components with a UV cut filter: Because blue light passes through, the organic EL element deteriorates and the screen becomes yellowish.

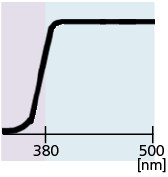

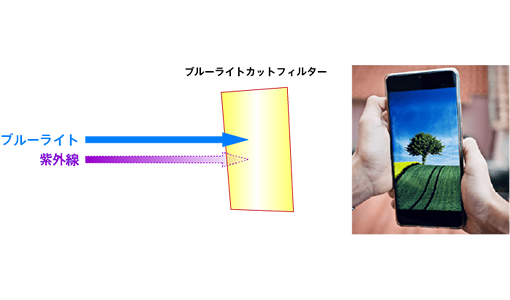

Image of protection of optical components by blue light cut filter: Since neither blue light nor ultraviolet rays are transmitted, it can be expected to prevent deterioration of organic EL elements and maintain a vivid screen.

glasses lenses

Effect 1: Can be expected to protect not only the eyes but also the pigments (organic substances) in the lenses.

By using our developed product, you can expect to protect not only your eyes but also the pigments (organic substances) in your lenses.

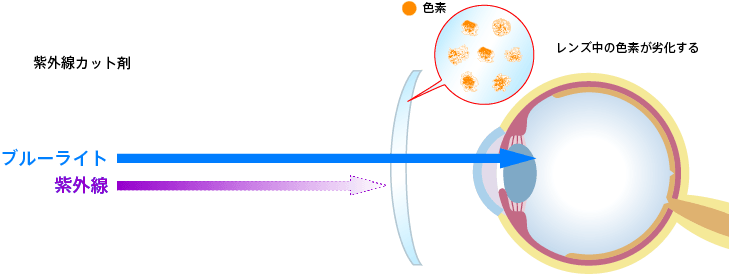

Image of protection of pigments in lenses using UV blocking material

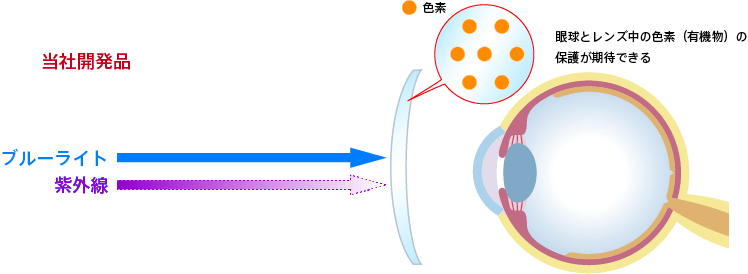

Image of protection of pigments in lenses using our developed product

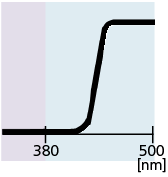

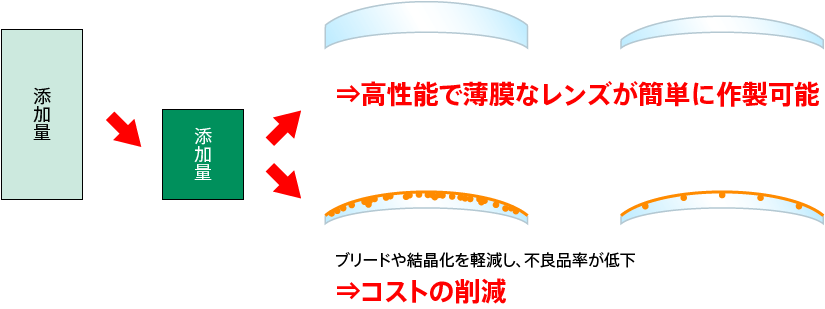

Effect 2: Strong absorption in the blue light region (380-400nm), resulting in high dosing efficiency.

Our developed product has strong absorption in the blue light region (380-400nm), so it has high dosing efficiency and allows for the easy production of high-performance, thin-film lenses. It also reduces bleeding and crystallization and reduces the efficiency of defective products, leading to cost reductions.

③ Medical packaging

Effect 1: Can cut ultraviolet rays and blue light by itself, and is effective in protecting various active ingredients such as vitamins.

Effect 2: Achieving high transparency and visibility

In addition, due to its unique new structure, it can be used in high-temperature processing, has high light resistance, and can protect active ingredients for a long period of time.

Inquiries

TOYOCOLOR CO., LTD. Functional Materials Sales Department

TEL:+81-3-3272-0956