Applied technology of “dispersion” Resist for color filter

Technology overview

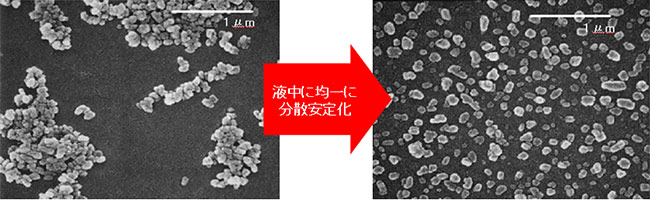

Additionally, color filter are required to have high light transmittance. In order to reduce scattered light, it is essential to have a technology that reduces pigments to nano-sized particles and disperses them uniformly. By applying special processing to the surface of pigments particles, our group is able to uniformly disperse and stabilize ultra-fine pigments in liquid without agglomerating them.

Product Case Studies

Our group's color resist are used in a variety of applications, including FPDs (flat panel displays), image sensors, and infrared (IR) sensors.

color resist for FPD

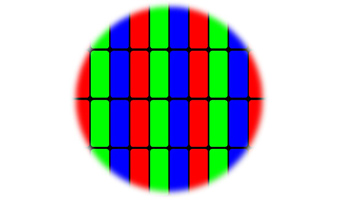

We support FPDs for a variety of uses, from mobile devices to large LCDs (liquid crystal displays). color filter for FPDs require high-definition patterning, high transmittance, and a wide color gamut, as well as coatability, high-speed coating, and precise photolithographic design.

High definition patterning

As displays become higher resolution, technology to form fine patterns is needed to make the outlines of images clear and sharp.

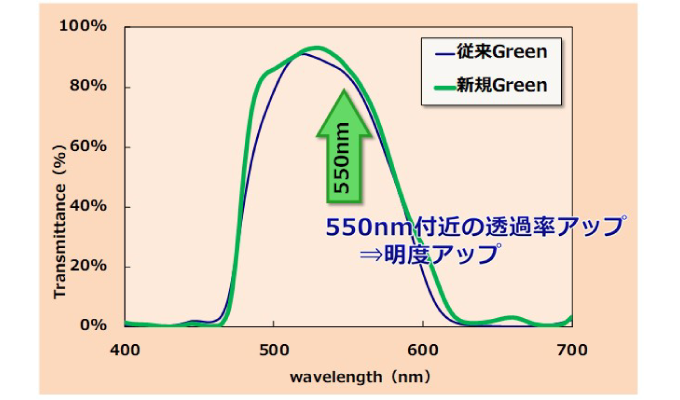

Higher transmittance, higher color gamut

Development of new colorants (OPTLION™ GREEN)

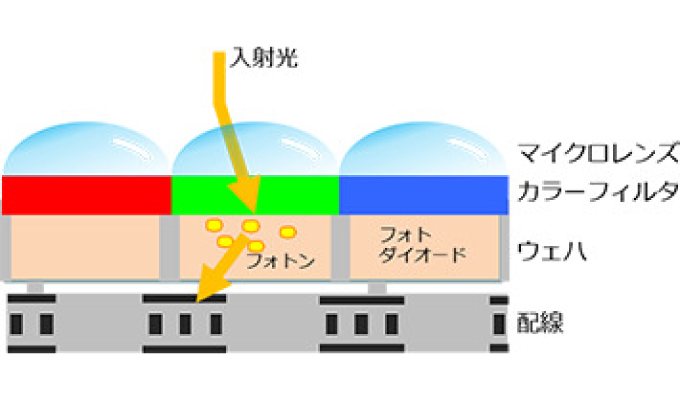

color resist for image sensor

Since the size per pixel is significantly smaller than that of a display, patterning technology that supports even higher definition is required.

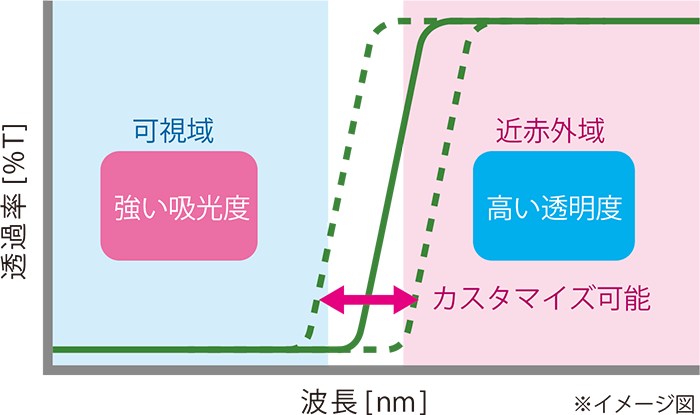

Near-infrared transmissive materials

Application example

Security cameras

Infrared light allows you to take pictures even in dark places

In-vehicle camera

Achieving a distance sensor using infrared light

Biometric (iris) authentication

Individual iris can be identified using infrared light