Business/Products

TOYOCHEM CO., LTD.

Toyochem Develops UV-curable Hot-Melt Adhesive with Heat Resistance Over 100°C

Quick cure technology eliminates aging process for faster processing speeds

This page has been translated using AI.

artience group 's TOYOCHEM CO., LTD. (President and Representative Director Yasushi Ariyoshi, Chuo-ku, Tokyo) is a UV-curable hot melts pressure sensitive adhesives" TOYOMELT ™ P-201 series" that has a heat resistance of 100°C or more that can be used for bonding steel components of automobiles and electronic devices, and that contributes to shortening the production process without the need for an aging process. Developed.

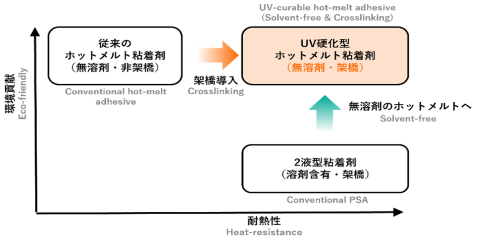

The UV-curable hot melts pressure sensitive adhesives" TOYOMELT ™ P-201 Series" developed by TOYOCHEM is a pressure sensitive adhesives that combines the characteristics of conventional solvent-based pressure sensitive adhesives and hot melts pressure sensitive adhesives.

Since the existing process requires a drying process and an aging process, it takes time to move on to shipping and secondary processing, and the energy costs and environmental impact associated with drying are issues.

On the other hand, hot melts pressure sensitive adhesives is an environmentally friendly adhesives that does not use organic solvents and does not require drying, but it is vulnerable to heat due to its characteristics of becoming liquid when heated and solidifying when cooled, and its use is limited.

The "TOYOMELT ™ P-201 Series" has a heat resistance of 100°C or more while being hot melts pressure sensitive adhesives by forming a cross-linked structure by UV irradiation. This makes it possible to use it for bonding steel components of automotive and electronic devices, which could not be handled by conventional hot melts pressure sensitive adhesives. In addition, it firmly adheres to a wide range of materials, from plastics such as polyethylene and polypropylene, which are generally difficult to bond, to metals such as aluminum and stainless steel (SUS), and glass. In addition, it has the unique property of maintaining rubber-like flexibility even after curing.

TOYOCHEM aims to be a company that can contribute to solving social issues around the world by matching elemental technologies born from its proprietary polymer technology with customer needs and developing innovative products together with customers.

June 02, 2025, Tokyo, Japan—Toyochem Co., Ltd., the polymers division of the artience Group, has developed the new TOYOMELT ™ P-201 Series of ultraviolet (UV) curable hot melt adhesives . The new hot melt product achieves heat resistance of 100°C and higher, making them suitable to meet the industrial demands of bonding steel components in such high performance applications as automotive and electronics devices. In addition, the P-201 Series applies an instant-cure technology for immediate tack and bonding ability, thus eliminating the need for the aging process. This leads to faster processing speeds and improved productivity for adhesives processors.

The new TOYOMELT ™ P-201 Series of UV hot melt adhesives from Toyochem were designed to address the environmental challenges related to solvent-based adhesives and the durability issues of hot melt types. Solvent adhesives typically require drying and aging, which results in costly time losses before the material can be shipped or transferred for secondary processing. The energy costs and environmental impact associated with the drying process have also been identified as challenges by the industry.

Moreover, while conventional hot melt adhesives are known to provide environmental advantages due to their lack of organic solvents or the need for drying ovens, one of their shortcomings is performance at elevated temperatures. These products are by nature susceptible to heat, which can lead to softening or loss of bonding strength, thus making them undesirable for use in high temperature environments.

To overcome these environmental and heat-related issues, Toyochem engineers in Japan applied UV-curing technology to chemically crosslink the hot melt adhesive by UV irradiation. “UV-curing technology offers an opportunity to create crosslinked structures that exhibit higher heat resistance at temperatures of 100°C or more. This makes it possible to do things that had been difficult to achieve with conventional methods,” said Taichiro Matsuoka, Division Director of Toyochem’s Packaging & Industrial Materials Sales Division. “Promising results in curing and heat resistance open new market opportunities for our customers, in particular in high performance applications like the bonding of steel components in automobiles or electronics devices. The new TOYOMELT P-201 Series expands our solvent-free adhesive range to our customers, as we continuously work to help them reach their technical and sustainability goals.”

In early evaluation testing, the TOYOMELT ™ P-201 adhesives demonstrate superior bond ability with difficult-to-adhere substrates of plastics like polyethylene (PE) and polypropylene (PP), metals such as aluminum and stainless steel (SUS), and glass. Furthermore, P-201 adhesives maintain a rubber-like flexibility even after it is cured or hardened, thus making it possible to bend and deform the adhesive without breaking.

The TOYOMELT ™ P-201 Series of UV hot melt adhesives are available now in global markets.

Related Pages

UV-curable hot melts pressure sensitive adhesives

https://www. artience group.com/ja/products/hotmelt/uv-hotmelt.html

###

Inquiries

TOYOCHEM CO., LTD.

Packaging & Industrial Materials Sales Division, Adre Sales Department, Sales Section 2

TEL:+81-3-3272-0764

Press inquiries

artience Co., Ltd.

Corporate Communication Department

TEL: +81-3-3272-5720

MAIL: info@artiencegroup.com