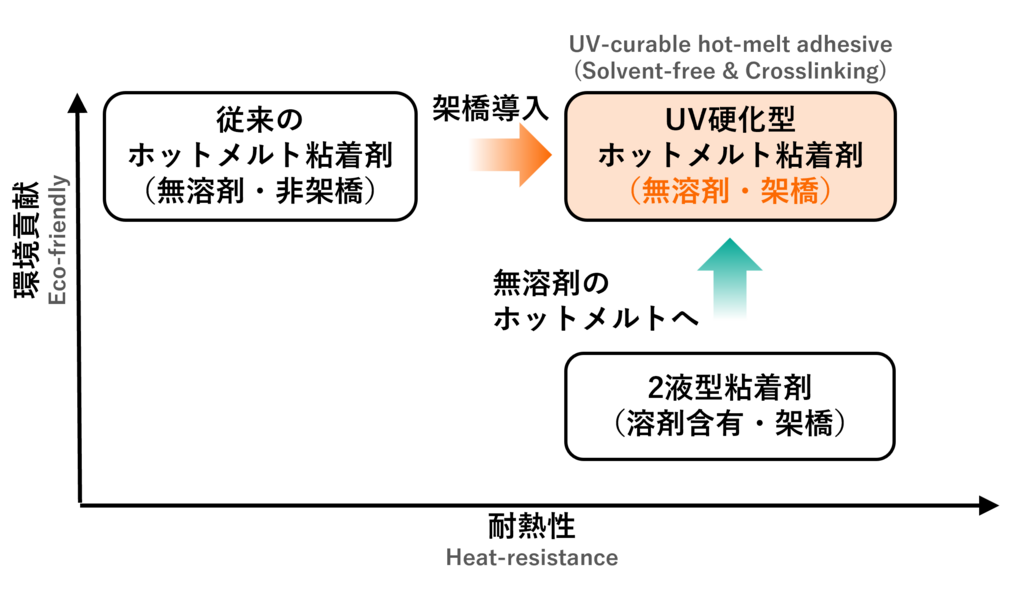

UV-curable hot melts pressure sensitive adhesives

UV irradiation gives heat resistance of 100°C or more & no aging required

Product Summary

For a detailed explanation of hot melts in general, please see the following page.

What is Hot-melt? Environmentally friendly adhesives

forte

- High heat resistance: Even at 100°C due to UV irradiation, there is no misalignment in the retention force test, and the pressure sensitive adhesives layer does not remain on the adherend during peeling.

- Solvent-free: 100% solids and solvent-free

- Strong adhesion: Strong adhesion to materials that are difficult to adhere (polyethylene, polypropylene, etc.)

- No aging: UV-curable type eliminates the need for aging and shortens the manufacturing process

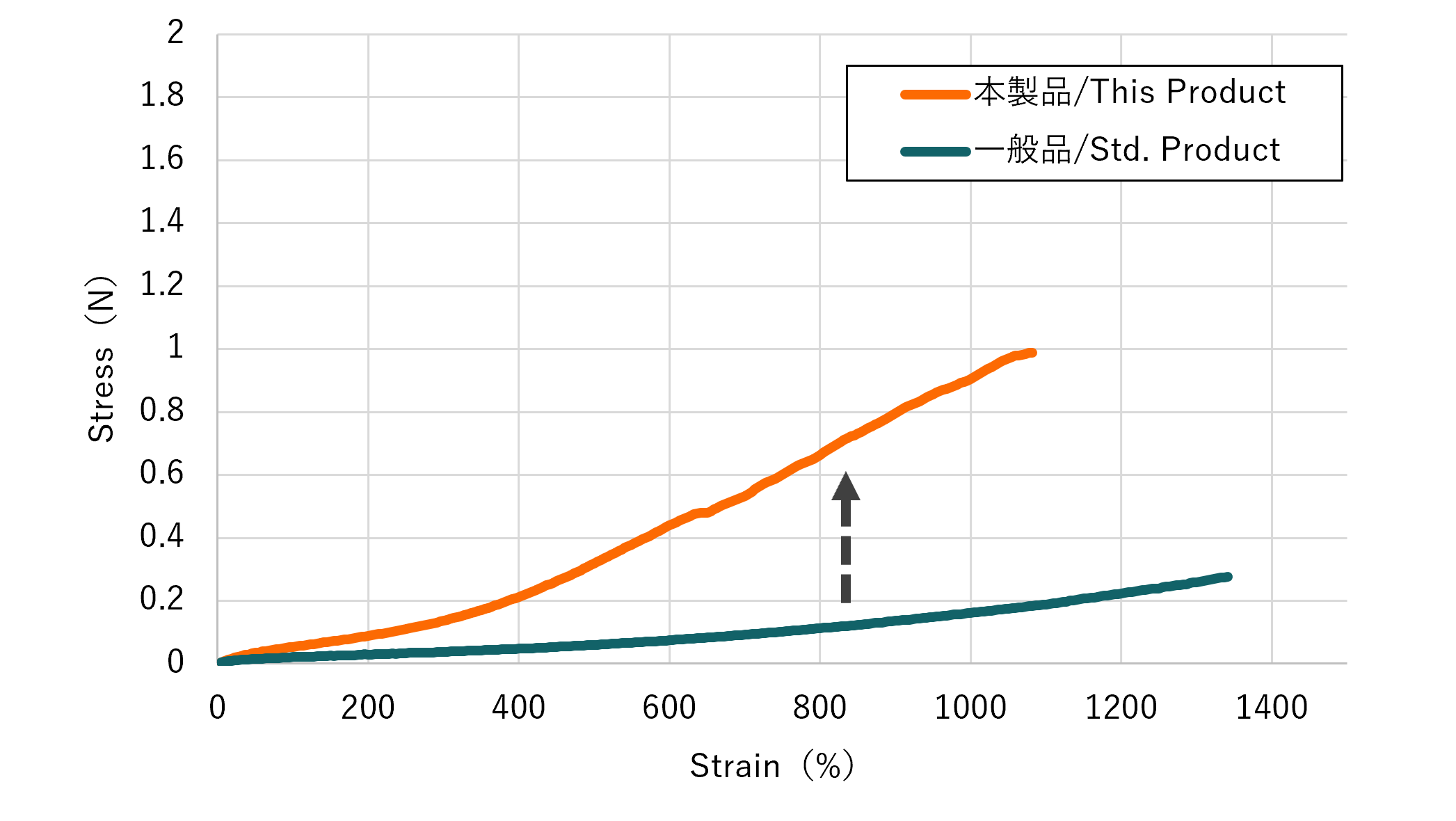

- Rubber-based material: Since the main component is synthetic rubber, it retains elastic properties (rubber-like flexibility) even after UV curing

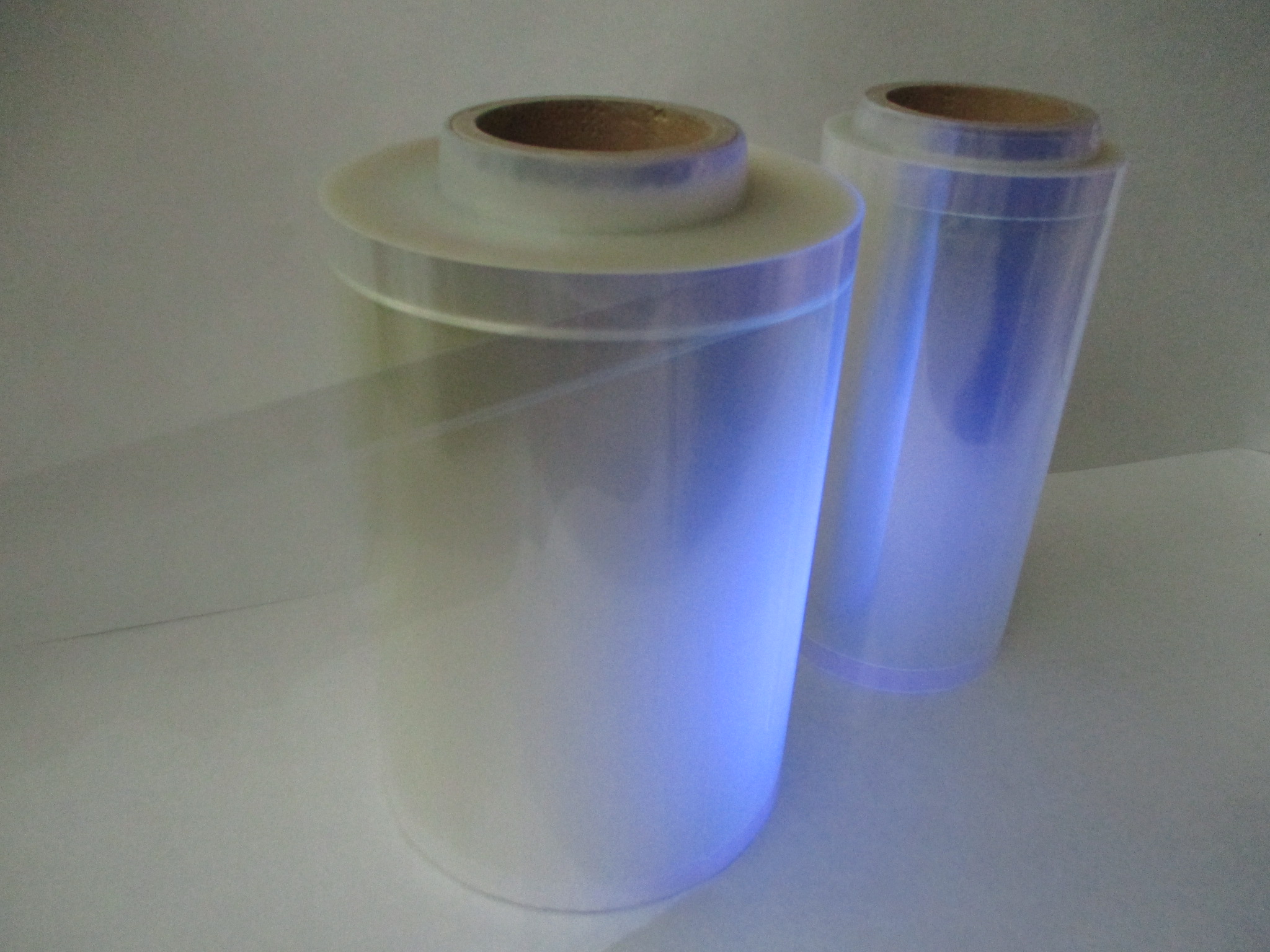

Appearance of the product before melting (solid form)

Exterior of UV hot melts pressure sensitive adhesives coated film

Application

Bonding and bonding of components in automobiles, electronics, and other industrial products

Applicable Scenes

(1) Replacement with solvent-borne products

- From the viewpoint of environmental considerations, I want to replace it with solvent-free pressure sensitive adhesives.

- We considered hot melts pressure sensitive adhesives, which is common as a solvent-free product, but it was rejected due to insufficient heat resistance.

⇒ This product can achieve both heat resistance of 100°C or higher and solvent-free

(2) Can be bonded to a wide range of materials & improved productivity

- Typical pressure sensitive adhesives does not have sufficient adhesion to olefin-based materials such as polypropylene

- It takes a long time to age and cure, and a large oven for drying is also required.

⇒ This product has high adhesion reliability for a wide range of materials such as olefin-based materials, metals such as SUS and aluminum, and glass. In addition, it can be cured in an extremely short time by UV irradiation, and can be used in a compact facility environment.

Performance

Basic physical properties

Numbers are representative

| Product name | TOYOMELT ™ P-201A | |

|---|---|---|

| Hue | Yellow transparent | |

| Softening point | 99℃ | |

|

Viscosity [mPa・s] |

180℃ | 5,100 |

| 170℃ | 6,200 | |

| 160℃ | 8,200 | |

| 150℃ | 12,250 | |

| 140℃ | 15,900 | |

| TOYOMELT ™ P-201A | General hot melts |

Third-party products UV-curable hot melts |

||

|---|---|---|---|---|

| Resin-based | Synthetic rubber | Synthetic rubber | Acrylic | |

|

Holding force Time to drop with a load of 1 kg [sec] or misalignment after 24hrs [mm] |

80℃ | No drops or misalignments | 224 sec | 2mm |

| 100℃ | No drops or misalignments | 82 sec | 8mm | |

|

Normal adhesive strength [N/inch] |

VS. SUS | 14.5 | 17.3 | 6.8 |

| To PP | 13.5 | 14.4 | 3.2 | |

|

Heat adhesive resistance [N/inch] |

VS. SUS | 4.5 | 0.5 | 1.8 |

|

Moisture permeability [g/m2-24hr] |

WVTR | 52 | 176 | 1,219 |

|

Dielectric constant [F/m] |

28GHz | 2.2 | 2.2 | 2.7 |

* Coating conditions: Film thickness 25 μm, base material PET #50

* Exposure conditions: High-pressure Hg lamp, integrated light intensity 900 mJ/c㎡, 1pass

* Heat adhesion: Measured under 120°C atmosphere

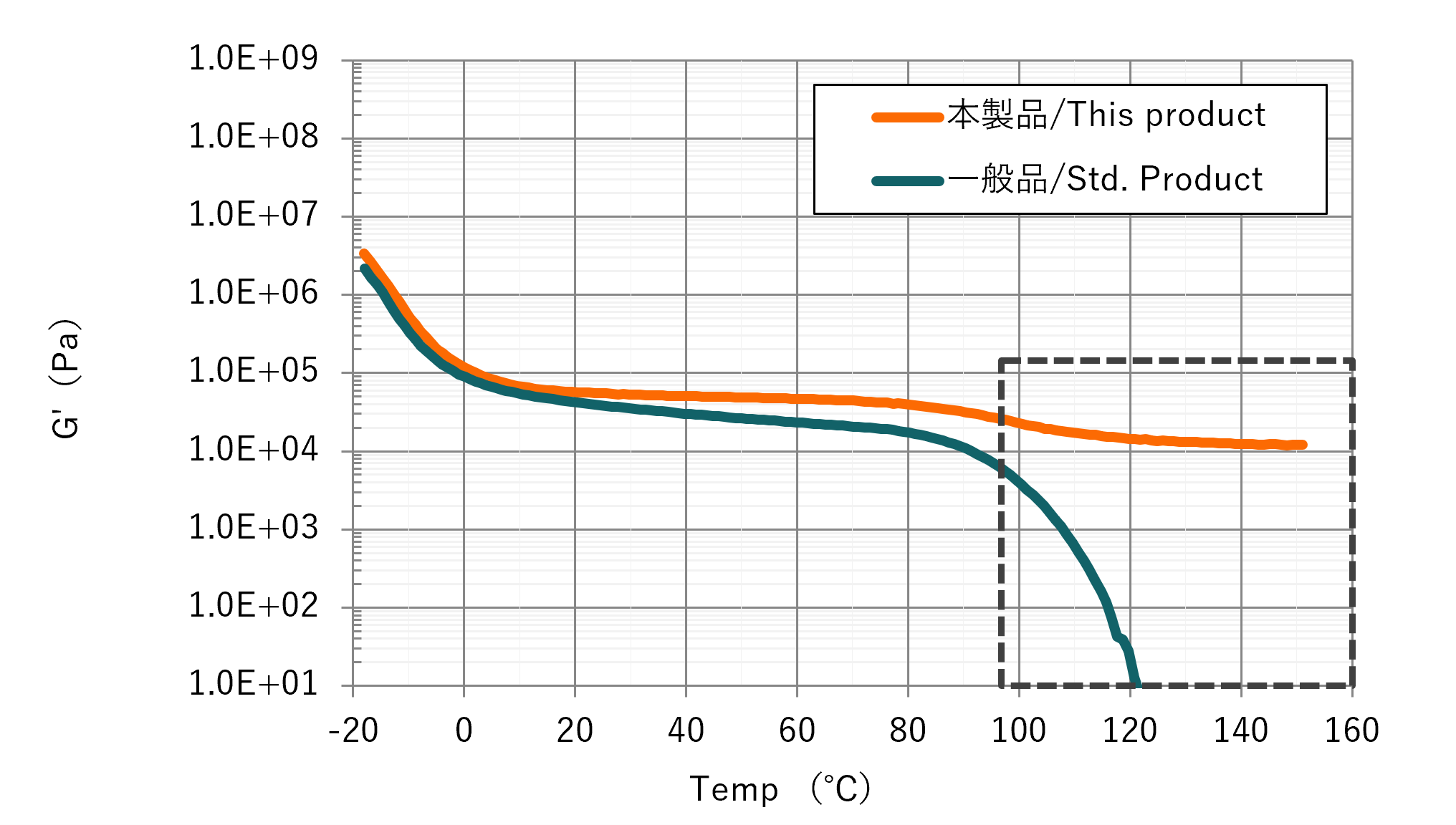

Flexibility Assessment

Storage modulus

Compared to common hot melts, this product maintains a rubbery area without a sharp decrease in storage modulus even at high temperatures above 100°C. By maintaining the storage modulus, it does not flow over time when used at high temperatures, preventing pressure sensitive adhesives from protruding from the end.

S-S Curve

Even after curing, it exhibits strength and elongation, and maintains elastic properties.

Usage method and equipment examples

Since this product is hot melts "pressure sensitive adhesives", it has stickiness (tack feeling) without completely sticking even after UV curing.

After UV curing, crimp and glue together.

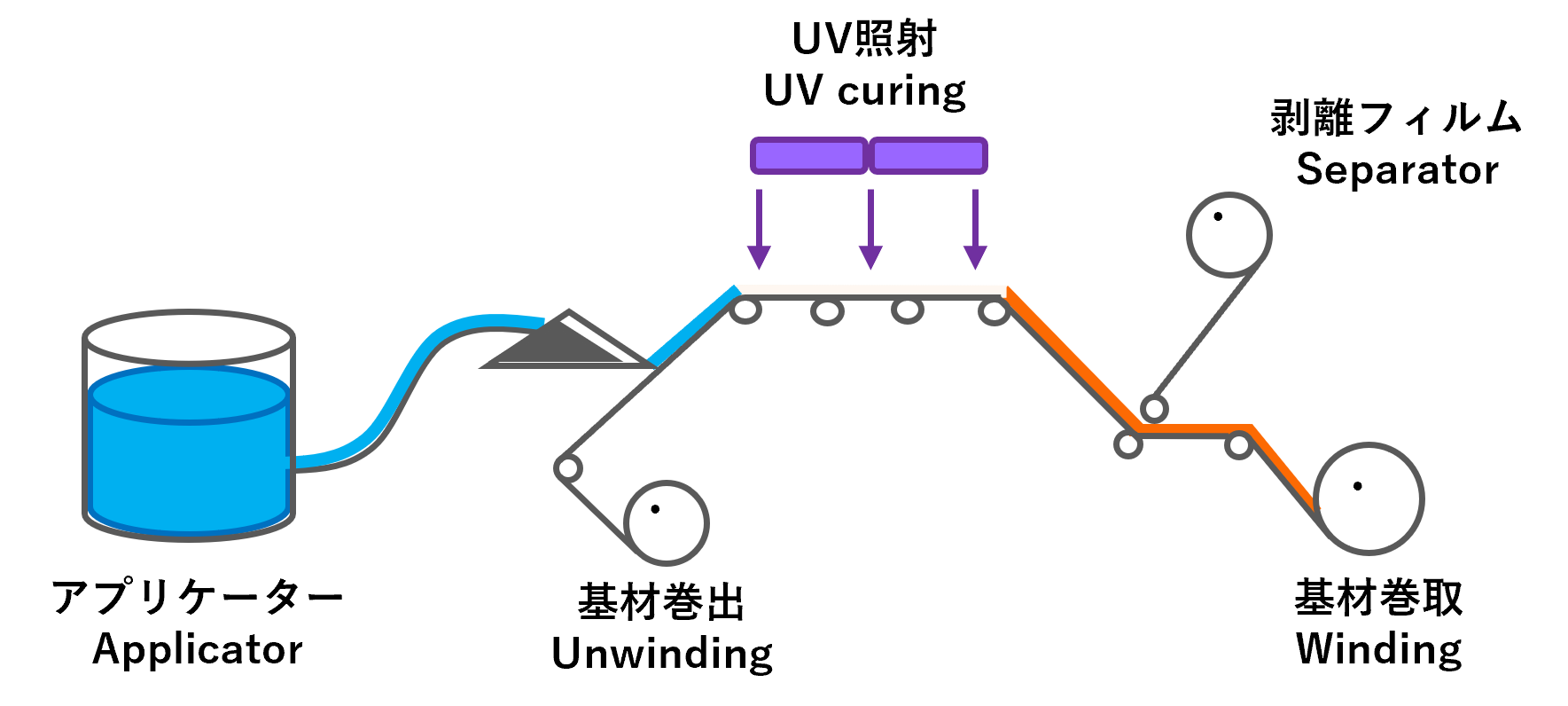

Example of equipment configuration when < is made into an adhesive film>

As with ordinary hot melts pressure sensitive adhesives, it is heated and melted at any temperature, and then applied with an applicator or coating machine. It is cured by a UV irradiation machine installed behind it.

<Other use cases>

It can also be applied directly to the metal or resin member to be bonded and used for UV curing.

Inquiries

TOYOCHEM CO., LTD. Packaging and Industrial Materials Sales Division Address Sales Department

TEL: +81-3-3272-3497