What is Hot-melt? Environmentally friendly adhesives

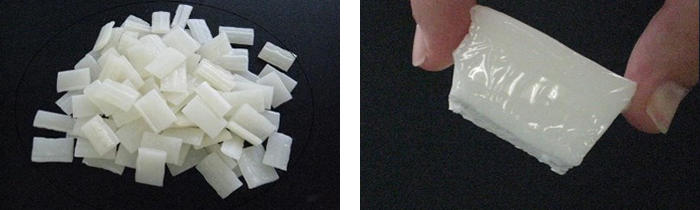

As the name "Hot + Melt" says, it is solid at ordinary temperature, but it melts and becomes liquid when heated. It is known as an environmentally friendly adhesives because it does not use organic solvents and does not require a drying process.

- Definition of Hot-melt

- Characteristics of Hot-melt

- Benefits of Hot-melt

- How to Coat Hot-melt

- Examples of hot melts usage

Definition of Hot-melt

- Solid-state adhesives at ambient temperature, based on thermoplastic polymers that do not contain any water or organic solvents.

- It solidifies in a short time by coating and cooling after heating and melting.

- Multicomponent system adhesives.

Hot-melt differs from other adhesives and has the following characteristics:

Characteristics of Hot-melt

- Becomes liquid when heated and solidifies when allowed to cool

- Does not contain organic solvent free.

- Depending on the base polymer, which is the main component, the characteristics and applications vary

Main base polymers for hot-melt and their properties

| Principal component | Characteristics | Main applications |

|---|---|---|

| EVA (ethylene vinyl acetate copolymer) | Due to its good compatibility with tackifiers and waxes, the degree of freedom in designing adhesive properties is high. Relatively cheap. | Bookbinding, cardboards, packaging, woodwork |

| Olefin | Better adhesion to PE and PP. Excellent heat resistance. | Packaging, building materials, automobile |

| Synthetic rubber (elastomer) | The adhesive layer has elasticity, and is excellent in adhesion to paper, a nonwoven fabric, and a film. | Sanitary materials, packaging |

| Reactive polyurethane (PUR) | Reactive Hot-melt that hardens by reacting with moisture and moisture. Heat resistance is high because it is not remelted by heat. It is also excellent in flexibility. | Building materials, automobiles, bookbinding |

| Polyamide | It is excellent in heat resistance, chemical resistance, and electrical insulation. | Electric and electronic components, automobiles |

| Polyester | Can be bonded to a wide range of materials. Superiorin thermal stability and durability. | Electric and electronic components, automobiles |

When using hot-melt, the following advantages and precautions are provided.

Benefits of Hot-melt

Improved productivity

- Saving energy and space due to no need for drying equipment

- Increased work speed due to quick adhesion

- Easy to automate the bonding process

Easy handling

- Contains no organic solvents, so there is less risk of poisoning or fire.

- No wastewater or waste liquid treatment is required.

- It is not a hazardous material, so there are less regulations in storage and transportation.

- Solid at room temperature, allowing e cient storage and transportation

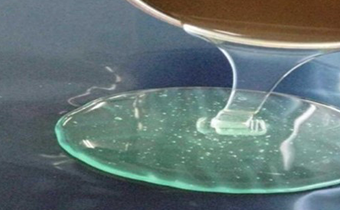

Adhesion to a wide range of materials is possible, and the coating pattern is also varied.

- Adhesion is possible not only to paper and metal, but also to difficult-to-adhere substrates (PP and PE)

- Various coating patterns such as dots, spirals, and roll coats can be made

Precautions for use

- Use at high temperatures, so caution should be exercised against burns.

- Easily deteriorated by prolonged heating

- Dedicated applicator (coating machine) is required.

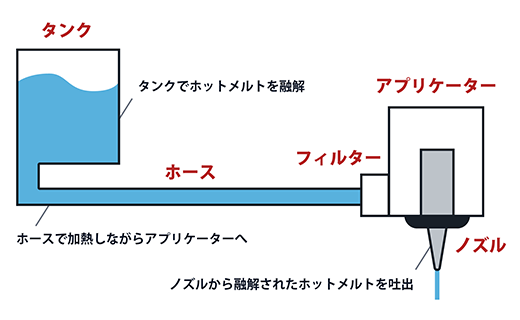

How to Coat Hot-melt

To coat Hot-melt, use a special "hot-melt applicator" (coating machine) with tanks, hoses, nozzles, etc., as shown in the illustration below.

Examples of hot melts usage

food packaging material

cardboard

Bookbinding

diapers and sanitary

Clear case

Solar cells backseat

Automobile mat

straw attachment

PET bottle body label

We have a wide lineup of hot melts products for a variety of uses. We also carry out improvements and developments according to customer requests, so please feel free to contact us.

Inquiries

TOYOCHEM CO., LTD. Packaging and Industrial Materials Sales Division Address Sales Department

TEL: +81-3-3272-3497