Agingless pressure sensitive adhesives significantly reduces shipping time

A two-component acrylic pressure sensitive adhesives that uses fast-curing technology to eliminate the need for an aging process.

Contributes to reducing time, energy, and space in the manufacturing process of adhesive processed products.

Contributes to reducing time, energy, and space in the manufacturing process of adhesive processed products.

What is agingless pressure sensitive adhesives?

Conventionally, the manufacturing process of adhesive processed products requires aging (curing),

The new product we are introducing here uses fast-curing technology to achieve non-aging acrylic two-component type.

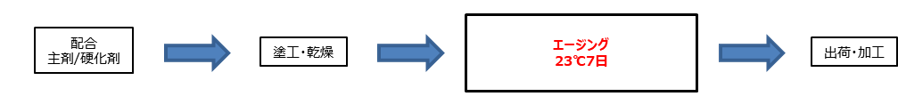

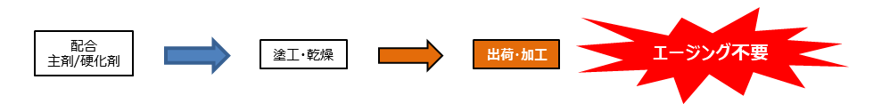

Manufacturing process of adhesive products

For conventional products

For non-aging pressure sensitive adhesives

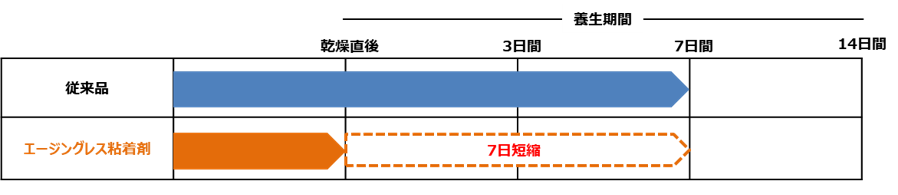

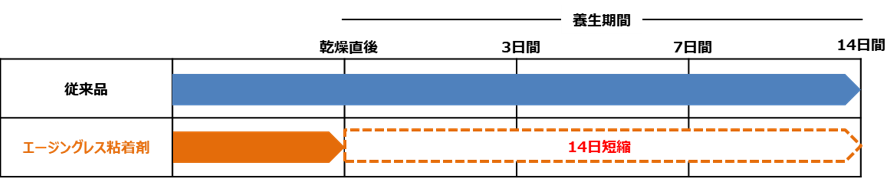

Time saving effect by curing temperature

At room temperature 23℃

In winter at 0℃

Expectations for agingless pressure sensitive adhesives

- Energy saving: Temperature control during curing is no longer necessary, contributing to energy savings.

- Time saving: No curing time is required, allowing for a significant reduction in lead time. By speeding up inspection pass/fail decisions, it also contributes to more efficient production planning.

- Space saving: No storage space is required during curing, contributing to space saving in the factory.

Introducing new products

Medium adhesive grade EXK 22-183

A general-purpose, medium-adhesion, non-aging pressure sensitive adhesives.

Sufficient adhesive properties are maintained even after coating has dried.

| BPS 6372 (general purpose product) | New product EXK 22-183 | ||

|---|---|---|---|

| NV/Vis | 52%/7000mPa・s | 52%/7500mPa・s | |

| After coating and drying (uncured) |

SUS adhesive strength, 24hrs [N/25mm] |

15.1 | 13.7 |

| holding power 70℃-1kg, 70000 seconds |

46000 seconds fall CF | 0.3mm | |

| 7 days after coating 23℃-50%RH |

SUS adhesive strength, 24hrs [N/25mm] |

13.9 | 12.0 |

| holding power 70℃-1kg, 70000 seconds |

0.5mm | 0.2mm | |

- Coating amount: 25g/㎡, Base material: PET50μm

- CF: Cohesive failure

High peel strength pressure sensitive adhesive grade EXK 22-184

A general-purpose strong pressure sensitive adhesives that does not age.

This grade has particularly good adhesion to olefins.

| BPS 5762K (general purpose product) | New product EXK 22-184 | ||

|---|---|---|---|

| NV/Vis | 45.5%/3800mPa・s | 50%/4800mPa・s | |

| After coating and drying (uncured) |

SUS adhesive strength, 24hrs [N/25mm] |

27.1CF | 19.6 |

| holding power 70℃-1kg, 70000 seconds |

40 seconds fall CF | 0.2mm | |

| 7 days after coating 23℃-50%RH |

SUS adhesive strength, 24hrs [N/25mm] |

19.5 | 19.6 |

| PP adhesive strength, 24hrs [N/25mm] |

15.2 | 18.5 | |

| PE adhesive strength, 24hrs [N/25mm] |

7.0 | 10.3 | |

| holding power 70℃-1kg, 70000 seconds |

0.2mm | 0.2mm | |

- Coating amount: 25g/㎡, Base material: PET50μm

- CF: Cohesive failure

Expected usage examples

For various tapes

・Curing tape

· double-sided tapes

For various labels

・Film label

- The above is just an example, so please feel free to contact us for any other applications.

Inquiries

TOYOCHEM CO., LTD. Packaging and Industrial Materials Sales Division Sales Department 1

TEL:03-3272-0940