PP for decorative filmsStrong adhesion, high durability pressure sensitive adhesives

PP (polypropylene) resin is often used in automotive exterior parts, so there was an urgent need to improve adhesion, but conventional pressure sensitive adhesives had problems with adhesion to olefin materials such as PP.

This time, TOYOCHEM has developed a pressure sensitive adhesives that achieves "strong adhesion" to PP components and "high durability" that can withstand automotive specifications.

Please check the following page for the characteristics of decorative film and the role of pressure sensitive adhesives.

What is pressure sensitive adhesives for decorative films?

Online InquiriesProduct Info

TOYOCHEM handles the following two products as PP pressure sensitive adhesives that can be used for decorative films.

Both have strong adhesion and high holding power, but product A is a type that is easier to reattach, and product B is more durable and has excellent heat resistance.

| Product name | Forming method | Resin-based | Features |

|---|---|---|---|

| Development Product A | OM-D (TOM molding) | elastomers | PP strong bonding, high holding force, heat resistance, low tack |

| Development Product B | OM-D (TOM molding) | acrylic | PP strong bonding, heat resistance, outgassing resistance |

Product features

Strong adhesion

Since decorative films are applied to a variety of materials, pressure sensitive adhesives must also be able to handle a wide variety of materials. For example, pressure sensitive adhesives is required to be applicable to PP and glass, which are considered difficult to bond.

Our pressure sensitive adhesives has strong adhesive strength against PP, SUS.

| Product name | Tack (N/25mm) * | ||

|---|---|---|---|

| PP 23℃ |

PP 80℃ |

SUS 23℃ |

|

| Development Product A | 36.2 | 31.3 CF | 35.5 |

| Development Product B | 28.6 | 17.4 CF | 28.1 |

- Composition: PP or SUS/ PSA 50μm / PET 50μm substrate

Low probe tack for easy reapplication

The relatively weak initial adhesive force allows for easy peeling and repositioning even after initial application.

| Product name | Probe Tuck (N) |

|---|---|

| Development Product A | 0.03 |

| Development Product B | 0.74 |

Processability that shows adhesive strength even after 200% stretching

Decorative films may also be applied to products with three-dimensional shapes, and pressure sensitive adhesives that can handle such complex shapes is required.

TOYOCHEM 's pressure sensitive adhesives has processability that sticks firmly to PP even after 200% stretching in an 80°C environment.

| Product name | 200% post-extension adhesion (N/25mm) * |

|---|---|

| Development Product A | 23.5 CF |

| Development Product B | 17.2 CF |

- TOM post-forming adhesive strength: 130°C-0.3Mpa-10sec

- Peel Condition: 180 Degree Peel, 300 mm/min

Real Pictures

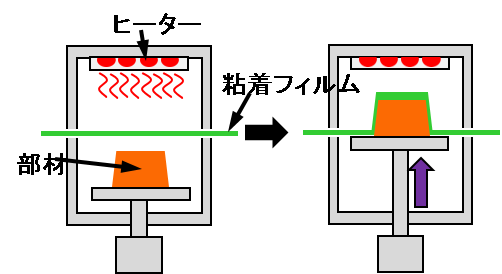

Forming method

Durability for long-term stable adhesion

The durable pressure sensitive adhesives maintains a stable bond over time. This prevents the decorative film from peeling off or floating off the product surface, ensuring that the product's appearance quality is maintained for a long time.

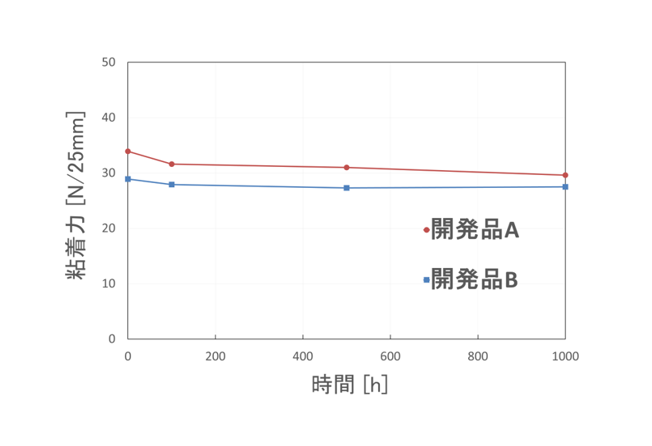

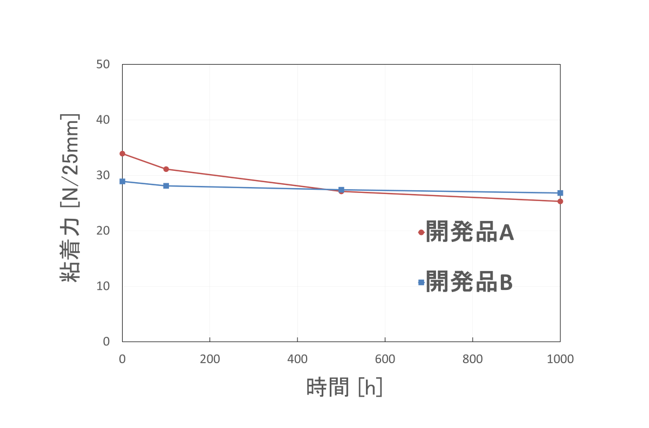

Our pressure sensitive adhesives has the durability to maintain its adhesive strength after being applied to hot water at 40°C and in an environment of 80°C.

Adhesive strength after 40°C hot water

Viscosity after 80°C

High heat resistance

Decorative films are used on the surfaces of various products, but the heat resistance of pressure sensitive adhesives is directly linked to the durability of the product, especially in places where it may be exposed to high temperatures, such as automotive interiors and electronics.

The use of heat-resistant pressure sensitive adhesives also prevents the film from peeling off or floating even in high-temperature environments. This allows you to maintain the appearance quality and functionality of the product for a long time.

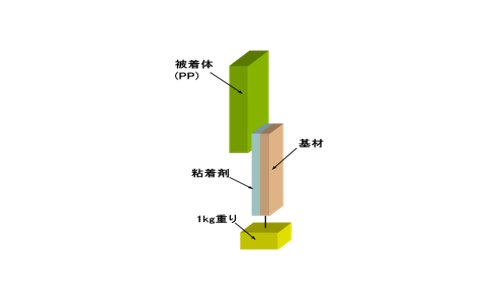

Our pressure sensitive adhesives is heat resistant and sticks strongly even after 1Kg of weight in an environment of 80°C.

| Product name | Holding force (80°C-1kg-70000s) | Constant load (80°C-100g-24h) |

|---|---|---|

| Development Product A | 1.5mm | 8mm |

| Development Product B | N.C. | 55mm |

| Our standard products | 7500 seconds fall | 54,000 Seconds Fall |

- Composition: PP/PSA 50μm/PET50μm substrate

- TOM post-forming adhesive strength: 130°C-0.3Mpa-10sec

- Joining area: 25mm×25mm (holding force), 25mm×100mm (constant load)

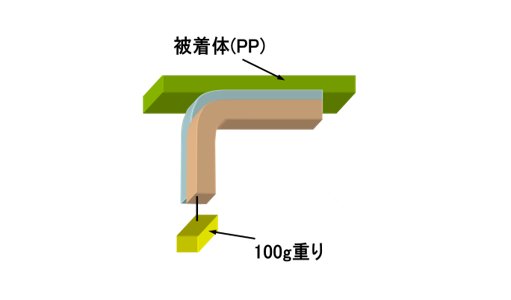

Holding Force Test

Constant Load Test

Expected Applications

Joining and bonding of parts and skin materials in automobiles and other industrial products

Inquiries

TOYOCHEM CO., LTD. Packaging and Industrial Materials Sales Division Sales Department 1

TEL:03-3272-0940