Pressure sensitive adhesives with dramatically reduces odor

Ideal for creating a comfortable indoor environment

Furthermore, with the development of EVs and self-driving technology, automobile interiors are increasingly becoming "living spaces," and demand for low-odor, low-VOC materials is increasing in search of a more comfortable environment. The need for low odor and low VOC products has become a global trend.

Utilizing our proprietary technology based on our experience in interior pressure sensitive adhesives, we have developed a low-odor, low-VOC pressure sensitive adhesives suitable for creating a comfortable indoor environment.

About odors and VOCs

Odor can be suppressed by reducing the VOC contained in pressure sensitive adhesives as much as possible.

- VOC: Volatile Organic Compounds

- There are individual differences in how odors are perceived.

Odor and VOC are correlated, so it is possible to achieve both control and reduction effects.

VOC (13 substances and T-VOC)

- VOC

There are approximately 200 types of volatile organic compounds.

The Ministry of Health, Labor and Welfare has provided guideline values for indoor concentrations for 13 of these substances. - T-VOC

This refers to the concentration level of a mixture of multiple VOCs, and the Ministry of Health, Labor and Welfare has indicated a provisional target value for indoor concentration.

| VOC | Indoor concentration guideline value [μg/m 3] |

|---|---|

| formaldehyde | 100 |

| acetaldehyde | 48 |

| toluene | 260 |

| Xylene | 200 |

| ethylbenzene | 3800 |

| styrene | 220 |

| Paradichlorobenzene | 240 |

| Tetradecane | 330 |

| Chlorpyrifos |

1 However, in the case of children, it is 0.1. |

| fenobucarb | 33 |

| Diazinon | 0.29 |

| Di-n-butyl phthalate | 17 |

| Di-2-ethylhexyl phthalate | 100 |

| Total volatile organic compounds (T-VOC) |

Temporary target value 400 |

* Source: Ministry of Health, Labour and Welfare "Indoor Concentration Guidelines for Chemical Substances in Indoor Air" (January 17, 31)

New product EXK 21-046

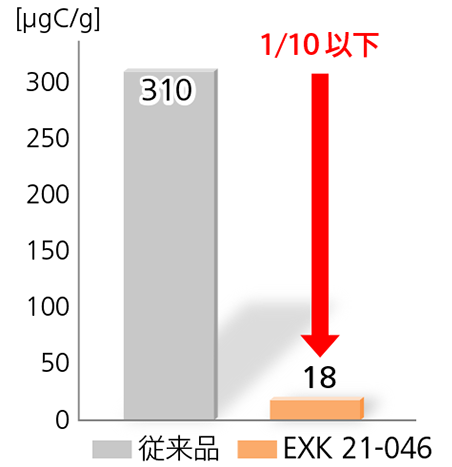

Although conventional low-VOC pressure sensitive adhesives can reduce 13 VOC substances, a small amount of T-VOC remains after the drying process, causing odor.

Therefore, we selected a material that does not easily remain in the paint film, and by making full use of our proprietary polymerization and compounding technology, we succeeded in reducing T-VOC and odor without sacrificing conventional adhesive properties by controlling viscoelasticity.

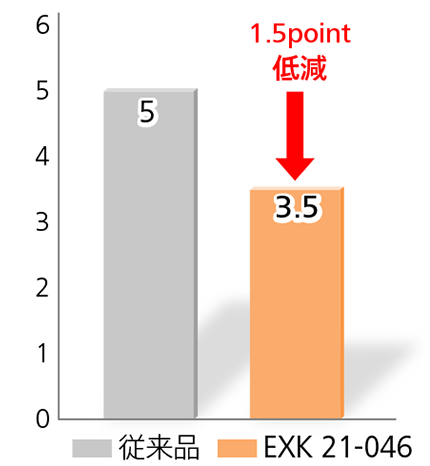

T-VOC content and odor comparison data

- Composition: pressure sensitive adhesives 65g/m2 / Non-woven fabric / pressure sensitive adhesives 65g/m2

- After drying at 105℃ for 2 minutes and curing for 7 days at 23℃ and 50%RH.

| Odor evaluation criteria | Profile |

|---|---|

| Grade 1 | Not noticeable |

| Grade 2 | Noticeable, not objectionable |

| Grade 3 | Clearly noticeable, but still not objectionable |

| Grade 4 | Objectionable |

| Grade 5 | Very objectionable |

| Grade 6 | Unbearable |

Adhesive performance

A low-odor, low-VOC pressure sensitive adhesives that is ideal for home and automobile interior applications.

| EXK 21-046 | Conventional product | |||

|---|---|---|---|---|

| BHS 8515 (crosslinking agent) [parts] | 3.1 | 2.5 | ||

| Peeling strength [N/25mm] | VS. SUS | 20 minutes after pasting | 24.5 | 22.1 |

| 24 hours after pasting | 23.3 | 21.1 | ||

| To PP | 20 minutes after pasting | 16.1z | 12.4z | |

| 24 hours after pasting | 16.6z | 12.5z | ||

| Shear [mm] | SUS 80℃-1kg-70,000 seconds | 0.5 | 0.2 | |

- Composition: pressure sensitive adhesives 65g/m2 / Non-woven fabric / pressure sensitive adhesives 65g/m2

- After drying at 105℃ for 2 minutes and curing for 7 days at 23℃ and 50%RH.

- z: zipping

Inquiries

TOYOCHEM CO., LTD. Packaging and Industrial Materials Sales Division Sales Department 1

TEL:03-3272-0940