Environmentally friendly pressure sensitive adhesives to achieve strong peel strength by lower coating weight

Advantages of thinner pressure sensitive adhesives

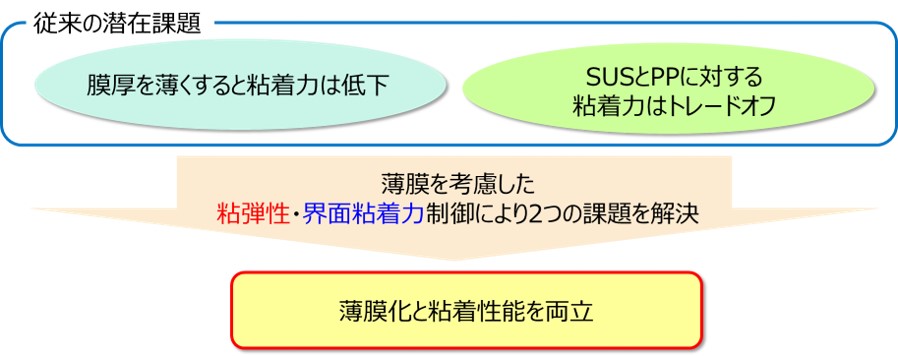

We have developed a new environmentally friendly pressure sensitive adhesives that has high adhesive strength even with a thin film thickness, which was difficult to do with conventional pressure sensitive adhesives.

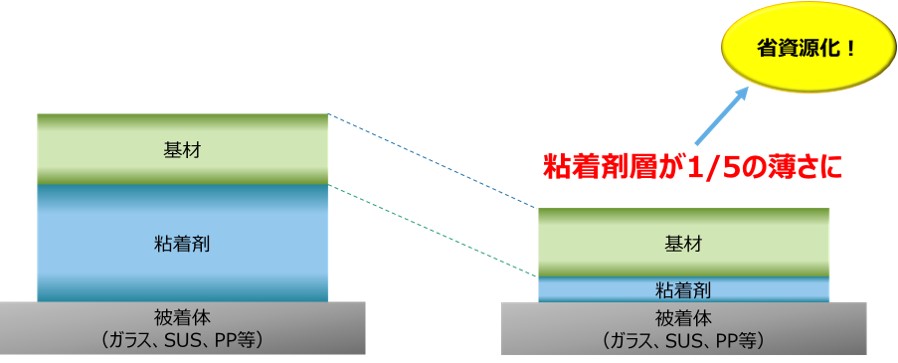

Benefit 1: Contributes to resource conservation

Because pressure sensitive adhesives layer is thinner, it contributes to resource conservation, such as by reducing the amount of raw materials used during production.

* pressure sensitive adhesives 25 μm → 5 μm

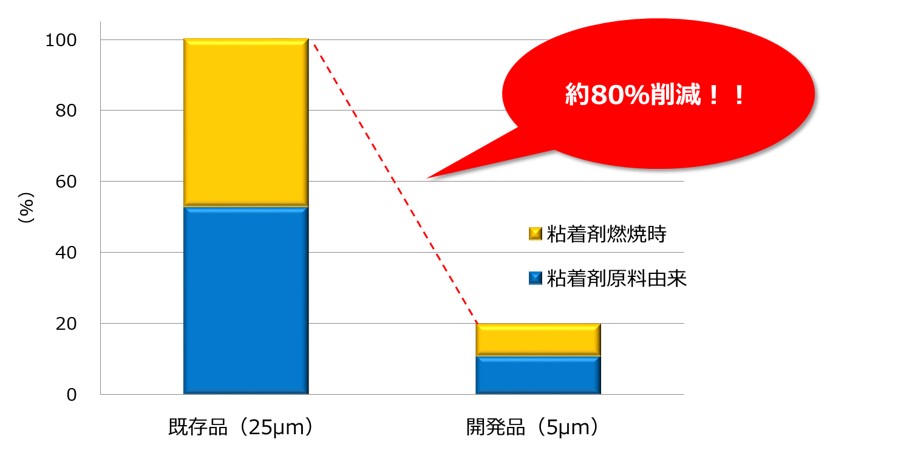

Benefit ②: Contributes to reducing CO 2 emissions

Because pressure sensitive adhesives layer is thinner, CO 2 from raw materials generated during production and CO 2 generated from combustion during disposal can be significantly reduced.

- The CO 2 emissions of the existing 25μm product is 0.283g/m2 as 100.

- Raw material procurement and combustion: We preferentially use IDEA version 2.2 [Climate Change IPCC 2013 GWP 100a], but some calculations are based on our own rules.

New product lineup

| thermosetting type | UV curing type | |

|---|---|---|

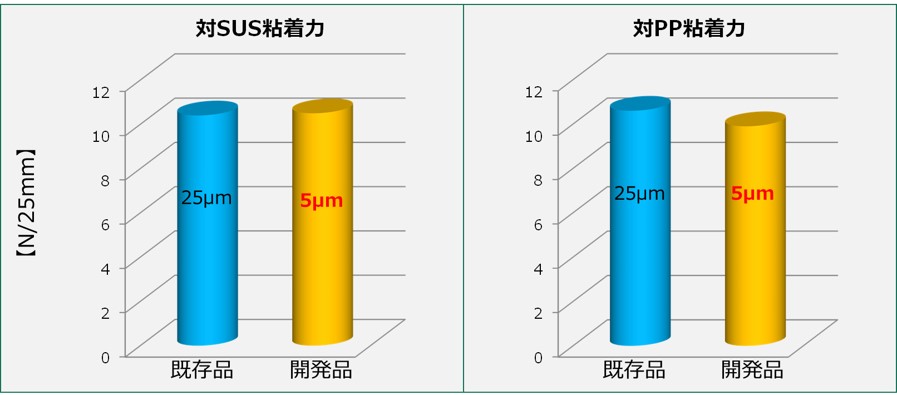

| Features | ・Exhibits high adhesion to both SUS and PP | ・No aging required due to UV curing ・Exhibits high adhesion to both SUS and PP |

Development product data

We compared it with existing solvent-based acrylic pressure sensitive adhesives (our STD product).

Even with a film thickness of 5 μm, the developed product shows the same adhesive strength as the existing product with a film thickness of 25 μm.

Inquiries

TOYOCHEM CO., LTD. Packaging and Industrial Materials Sales Division Sales Department 1

TEL:03-3272-0940