Peeling and antifouling coatings FLUSHED™︎

In addition, migration, which is a weak point of silicone coatings, is minimized as much as possible. Ideal for release film and antifouling coating applications.

- Characteristics

- Product Info

- Coating surface condition

- Basic physical properties of coating film

- Applications

forte

Features ① Mold releasability

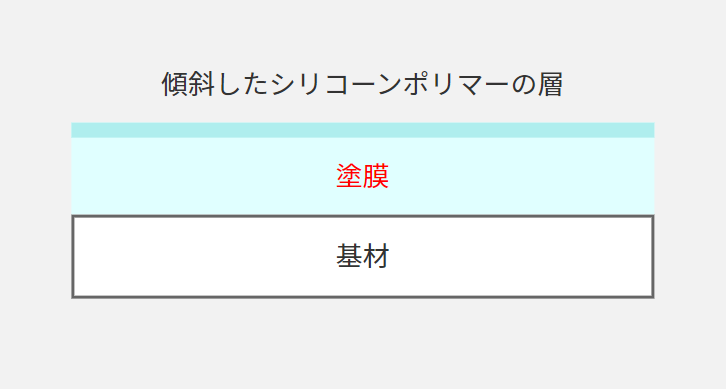

Because the silicone polymer is sloped on the base material surface, it has excellent releasability from the target object.

It is possible to customize the peeling force according to your needs.

| Peeling force | |

|---|---|

| SUR700 standard product | 180g/25mm |

| SUR700 Silicone increased product | 10g/25mm |

Test method: Speed 0.3m/m (measured with NITTO 31B tape)

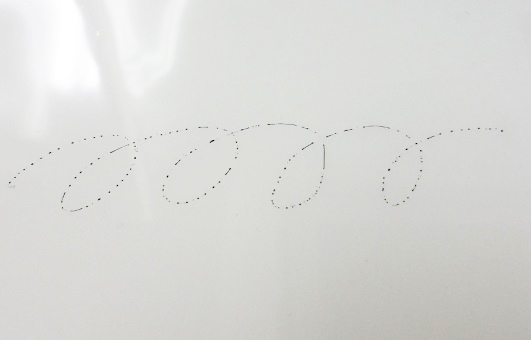

Feature ② Stain resistance

Water and oil repellency prevents dirt from adhering.

Also, any dirt that has adhered to it can be easily removed.

Product Info

| Product name | SUR700 | SUR700 hardener |

|---|---|---|

| Main agent | hardening agent | |

| composition | silicone modified acrylic resin | isocyanate compound |

| Appearance | light yellow translucent | Colorless and transparent |

| viscosity | Zahn Cup #4/29 seconds | ー |

| Solvent | Ketone type | Ester type |

| Non-volatile content | 33% | 75% |

| mixing ratio | Main agent/curing agent = 100/17 | |

| Aging conditions | 40℃×3 days or room temperature×1 week | |

* The above values are representative and not guaranteed

Coating surface condition

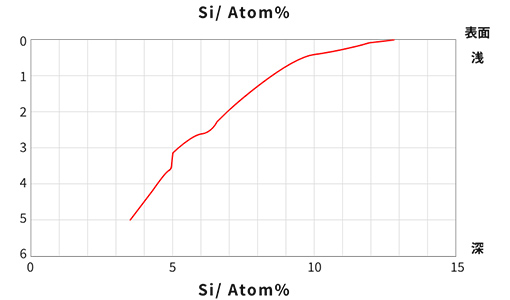

The silicone component is tilted to the surface of the coating film, resulting in release and antifouling properties.

Gradient degree of silicone polymer in coating film

Coating film image diagram

Basic physical properties of coating film

| Item | SUR700+ hardener | Test method |

|---|---|---|

| Film thickness | 3μm | Measured with a film thickness meter |

| Scratch resistance | ○ | Steel wool #0000 load 250g x 10 reciprocations 〇No scratches ▲Slight scratches x Scratches |

| magic wipeability | ○ | After writing on the paint surface with marker ink, wipe it off with a cloth and visually observe the paint surface. 〇No evidence ×There is evidence |

| Pencil hardness | 2H | Compliant with JIS K5400 |

| Peeling force | 180g /25mm |

Speed 0.3m/m (measured with NITTO 31B tape) |

Coating conditions

Base material: untreated PET100μm

Coating: Bar coater #6 Drying: 100℃ x 60 seconds Aging: 40℃ x 3 days

Applications

- release film

- antifouling coating

Inquiries

TOYOCHEM CO., LTD. Packaging and Industrial Materials Sales Division Sales Department 1

TEL:+81-3-3272-5743