Features of the Wide Color Rendering Process Ink KALEIDO™ Series

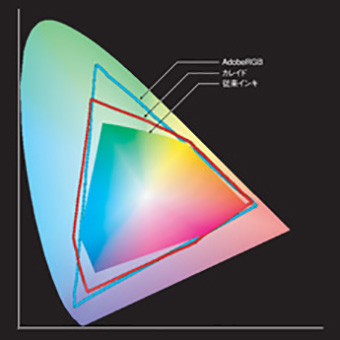

Although it is a four-color process ink, the KALEIDO™ can cover almost the color reproduction area of AdobeRGB, and reproduces vivid colors and smooth gradations that could not be achieved with conventional ink printing.

- Features of Wide Color Rendering Process Inks KALEIDO™

- Features of Wide Color Rendering Process Inks Kaleido Plus™

- KALEIDO™ Series Certification System

- Points to keep in mind when printing with wide color rendering using KALEIDO™ inks

Features of Wide Color Rendering Process Inks KALEIDO™

Closer to Adobe RGB KALEIDO™

In today's world where printed manuscripts are produced using digital data, photographs are taken and edited based on the color expression method (RGB color system) on the display (monitor) and designs are created. These printed documents are converted to the color representation method of printing inks (CMYK color system) just before printing, which is the final process.

However, if you try to print with a conventional process (4 colors), you will not be able to reproduce the colors you want because the color representation area of general CMYK (Japan Color, etc.) is much smaller than that of RGB. In particular, the elements of color expression, such as highly saturated (vivid) colors and smooth gradation, which are important for commercial printing design, were greatly impaired.

In such cases, in order to expand the color reproduction area of printing, multi-plate printing such as six- and seven-color printing (high-fidelity color printing) with the addition of intermediate color plates and spot color printing has been carried out, which has made it difficult to separate plates (RGB → print color conversion) and has led to an increase in costs.

TOYO INK ADDRESSES SUCH CONCERNS FACED BY PRINTING COMPANIES, DESIGNERS, CREATORS, AND CLIENTS BY TAKING THE APPROACH OF "PURSUING THE PROCESS PRINTING COLOR REPRODUCTION REQUIRED BY USERS WITHOUT ADHERING TO THE GENERAL STANDARD CMYK." We have developed a KALEIDO™ and have secured a CMYK color reproduction area that can solve these problems.

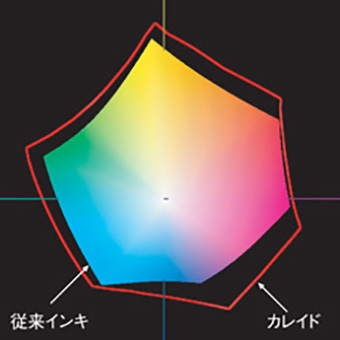

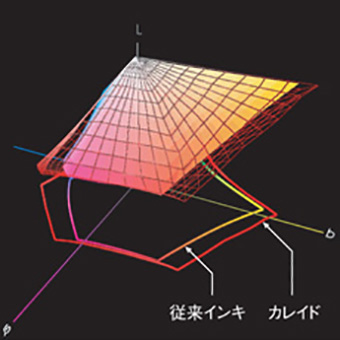

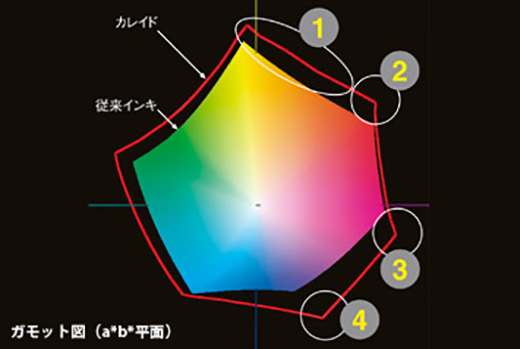

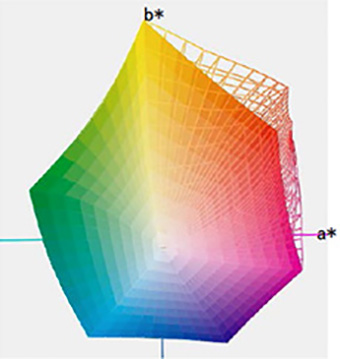

The figure above is a "gamut diagram" that shows the color range that can be recognized by the naked eye in 2D and 3D of hue/saturation and lightness, and the color representation area of AdobeRGB is shown by a light blue border. The dark gradient area in the center is the color reproduction range of conventional inks (standard process inks such as Japan Color), and the red border indicates the color reproduction range of the KALEIDO™.

Compared to conventional inks, KALEIDO™ dramatically expands the range of color reproduction, and it can be seen that it is much closer to the color expression range of AdobeRGB.

Color reproduction that cannot be achieved with conventional inks

The "expansion of the CMYK color reproduction range realized by KALEIDO™" that can be confirmed in the gamut diagram appears as the following effect in the actual image.

- It has a much wider color reproduction range than conventional inks and richer gradations from yellow to red.

←With conventional inks, the color reproduction range between yellow and red is narrow, so the vividness of the orange color is lost, resulting in a muddy gradation. - The gradation reproduction of strong reds has also been improved.

← Conventional inks cannot reproduce vivid red colors, resulting in a slightly heavy dark red color. - The magenta color is vivid, and the reproduction from white to pink is especially beautiful.

←The magenta of conventional inks is not sufficiently vivid, resulting in vague tones. - In particular, dark blue, which was difficult to reproduce in printing until now, has been dramatically improved in terms of gradation and color reproduction in KALEIDO™.

← conventional inks have not been able to produce strong blue colors with an impact.

Improved reproducibility for AdobeRGB

Many of the photographic images used in the design field are in AdobeRGB mode due to the improvement in the performance of digital camera devices.

In the figure below, when trying to reproduce an AdobeRGB image with conventional ink and KALEIDO™ ink, the area that cannot be reproduced (the part that goes beyond the color reproduction range of the ink) is represented by "dark green".

The added value of KALEIDO™ printing

KALEIDO™, an epoch-making process ink that realizes wide-color rendering printing, enhances the value of color printing.

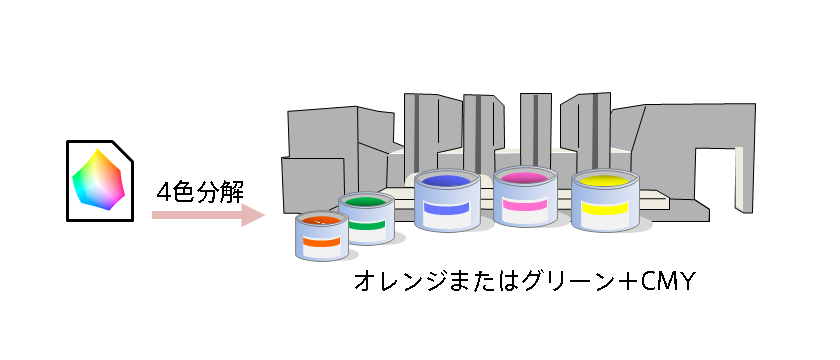

6-color/7-color printing level color reproduction

The KALEIDO™ with a wider color reproduction area can reproduce the same colors as 6-color and 7-color (high-fidelity) printing with the 4-color printing machine you are currently using. This leads to cost reduction and power saving in printing, and it is possible to produce printed materials with high color quality even at printing sites with only four-color machines.

Final print close to AdobeRGB image

Wide color rendering printing with KALEIDO™ realizes the final printed product as close as possible to the image on the designer's or creator's PC monitor.

This makes it possible to provide products with high client satisfaction.

Dedicated ICC profiles create KALEIDO™-quality proofs

With a dedicated KALEIDO™ profile, you can check the design on the monitor or output the proof with an inkjet printer KALEIDOYou can check the color reproduction close to the final printed product with ™ ink.

Features of Wide Color Rendering Process Inks Kaleido Plus™

Difference Between Kaleido Plus™ and Traditional KALEIDO™

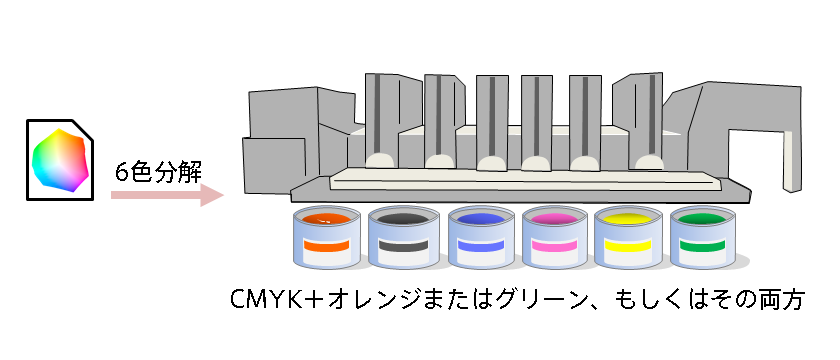

Kaleido Plus™ 2.0 is now available in four colors of conventional KALEIDO™ CMYK. With the addition of a new orange and green lineup, it achieves approximately 120% of the color expression of conventional KALEIDO™ by printing in up to 6 colors. The biggest feature is that by combining four colors such as CMY + orange and CMY + green, it is possible to reproduce a highly saturated color range even with a four-color machine, and the reproduction level is excellent. In line with this, we have launched a new "Kaleido Plus™ Printing Certification System."

Printed images of KALEIDO™ and Kaleido Plus™

Color separation uses a color conversion table (ICC profile) that achieves harmony between gray balance and color expression based on our proprietary technology.

Color separation can be converted using existing software using our conversion tape (ICC profile).

Kaleido Plus™ Expansion of the color representation area with 2.0 (compared to conventional KALEIDO™; CIE a*b* plane)

Orange hue comparison CIE a*b*

Green hue comparison CIE a*b*

Comparison of hues of orange and green CIE a*b*

* Gradient shapes have a traditional KALEIDO ™ color gamut

About Kaleido Plus™ Profiles

In Kaleido Plus™, we perform color separation using ICC profiles that enable multi-color conversion on Adobe® Photoshop®. TOYO INK Kaleido Plus™ ICC profiles that incorporate proprietary color conversion technologyDeveloped for: This profile is available in a lineup according to the number of colors used for printing, and is available for a fee. For details, please contact our sales representative or contact us using the inquiry form below.

KALEIDO™ Series Certification System

The KALEIDO™ series certification system is a TOYO INK that provides printing companies, output equipment, and systems with wide color rendering process inks. It is a system that certifies that the color reproduction of KALEIDO™ has been established. There are four certification systems: "Print Certification", "User Proofing Certification", "Output Device Certification", and "Digital Proof System Certification".

In the KALEIDO™ series certification system, the TOYO INK CO., LTD. has establishedThe certification standard is compliance with the KALEIDO™ series color reproduction standards.

Printing companies that meet the certification standards, as well as output equipment and systems, are posted on our website.

Kaleido Plus™ printing certification requires the acquisition of KALEIDO™ printing certification (conventional process 4 colors). In addition, for Kaleido Plus™ certification, the "Kaleido Plus™ ICC Profileand Kaleido Plus™ Starter Kit. For authentication methods, please contact our sales representative or contact us using the inquiry form below.

Points to keep in mind when printing with wide color rendering using KALEIDO™ inks

The need for color management

In order to achieve wide color rendering printing, it is necessary to "standardize printing" to suit each printing site, and to achieve this, color management in the prepress and press processes is essential.

Although CTP installation is a prerequisite, we recommend an environment where you can manage colors using ICC profiles, adjust plate making curves, and adjust dot gain on printing machines.

In addition, TOYO INK provides support services for "printing standardization" for printing companies.

Thorough density control at printing sites

KALEIDO™ inks have a higher clarity of yellow, red, and indigo inks, so they have a lower visual density than regular inks (products corresponding to Japan Color).

In the printing process, use a densitometer and thoroughly control the concentration.

Inquiries

TOYO INK CO., LTD. Digital Support Department Color Communication Development Group

TEL:03-3272-7693