water-based flexo ink AQUA PK Bio series

A general-purpose water-based-based flexo ink for packaging and paper bags with excellent printability and physical properties.

It uses plant-derived raw materials and meets the biomass certification standard of ``biomass content of 10% or more''.

Features of AQUA PK Bio

Product design with consideration for the environment and safety

This product uses plant-derived raw materials and meets the Japan Organic Resources Association's biomass certification standard of ``biomass content of 10% or more''. (Japan Organic Resources Association Biomass Mark Certification Number: 170030)

In addition, it is a non-hazardous material (water-based ink) under the Fire Service Act, and we take into consideration the safety of the working environment.

In addition, it is a non-hazardous material (water-based ink) under the Fire Service Act, and we take into consideration the safety of the working environment.

- About the Biomass Mark: The Japan Organic Resources Association aims to promote the comprehensive and effective use of organic resources and contribute to the creation of a sustainable recycling-oriented society and the promotion of environmental conservation. Products that use biological resources (biomass) and whose quality and safety comply with relevant laws, standards, standards, etc. are designated as Bimass Mark-certified products, and the mark is issued.

General-purpose water-based based flexo ink for packaging and paper bags with excellent printability and physical properties

- The above is an example of our evaluation and does not guarantee performance. Please note that this may vary depending on printing conditions, base paper, etc.

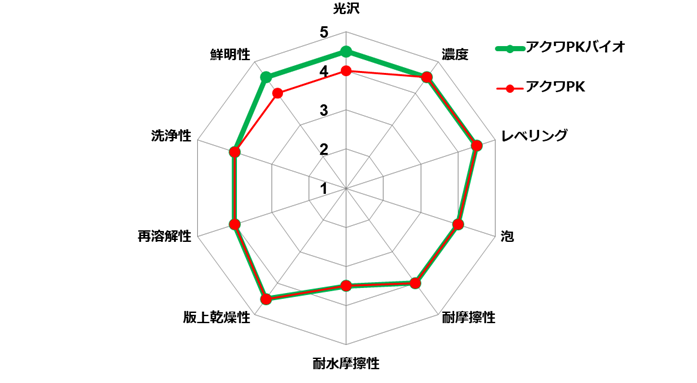

It has excellent printability and can be used in a wide range of paper applications such as wrapping paper and square bottom bags. The ink is designed with high concentration, odor and hygiene in mind. Various physical properties are equivalent to the current ink "AQUA PK", and good coating film properties can be obtained.

how to use

Dilution solvent/printing viscosity

- Diluent: Usually use water.

- Printing viscosity: Undiluted, preferably diluted with water, in Zahn Cup #4 for 11~15 seconds (25°C).

storage

- Avoid storing in high temperatures, direct sunlight and low temperatures.

- Filter the remaining ink and store it in a sealed state.

Inquiries

TOYO INK CO., LTD. Marketing Headquarters

TEL:03-3272-7693