Modified polyolefin Liothene™ / LIOFLEX™

Liothene™ and LIOFLEX™ are chlorine-free modified polyolefin products.

Polypropylene with improved adhesion to polar base materials such as metals and PET by combining functional groups. It contributes to improved adhesion between metals/PET and polypropylene materials. Liothene™ is as a powder and LIOFLEX™ as a dispersion.

forte

Good adhesion

- Excellent adhesion to metal base materials (SUS, aluminum, galvanized, etc.) and polypropylene materials

Heat resistance adhesion

- Due to its high melting point, it has excellent heat resistance and can be processed at high temperatures.

Food sanitation characteristics

- Compliant with FDA175.105

Property value

| Liothene | LIOFLEX | |

|---|---|---|

| Appearance | powder | cloudy liquid |

| Non-volatile content | >98% | 10% |

| acid value | 8 | 8 (solid equivalent) |

| Melting point | 155℃ | 155℃ |

| Melt viscosity (MFR)/viscosity | 70g/10min | 1,500mPa・s |

| Particle size D50 | 400μm | 20μm |

| Particle size D90 | 800μm | 70μm |

* The above values are representative and not guaranteed

Expected applications/markets

- Various primers

- paint additives

- Adhesives

- modifier

- Next-generation battery components (fuel cells, storage batteries, solar cells, etc.)

Can be used for a wide range of purposes such as

Example of use

Product Data

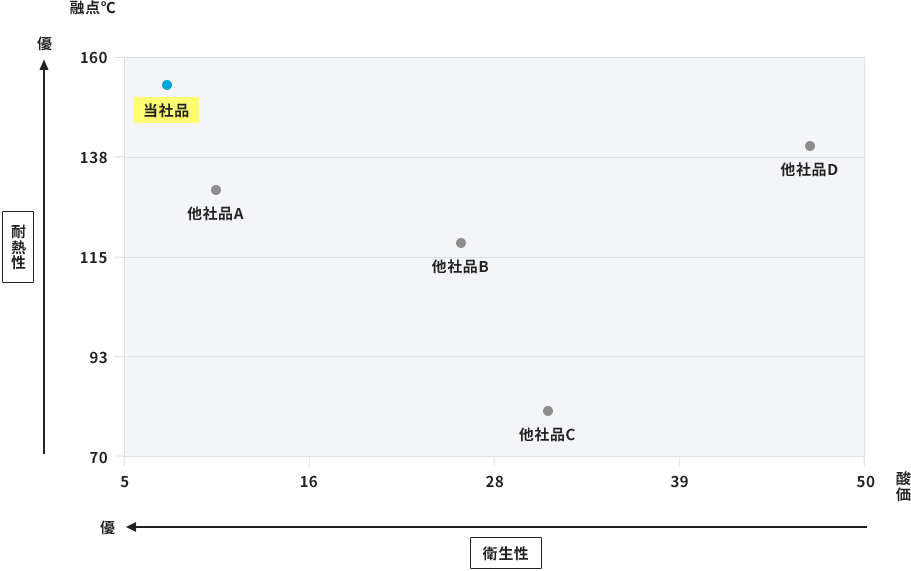

Heat resistance/hygiene

- Our products have a high melt viscosity and exhibit an adhesive function with a low amount of additives. * Recommended dosage: 3~20% (in total solids)

- There is very little residual unreacted material or low molecular weight material, and even with a low acid value, the adhesion to various substrates is improved.

- Additionally, due to its high melting point, it is ideal for applications that require heat resistance, heat-resistant adhesion, and retort resistance.

Adhesion (coating film physical property data)

Strongly bonds metal and PP sheet and maintains adhesive strength even after various tests.

| Adhesive force (N/20mm) | erichsen test | Cold resistance | Boiling water test | Heat resistance | |

|---|---|---|---|---|---|

| normal condition | After boiling water immersion | ||||

| 52 | 48 | ◎ | ◎ | ◎ | ◎ |

◎=No peeling

Sample preparation conditions

| Adhesives | adhesives containing Liothene |

|---|---|

| Base material | Electrogalvanized plate and PP resin sheet for 42002K |

| laminating temperature | 200℃ |

| Standard film thickness | 4μm |

| standard laminate crimp | 5Kg/cm2 |

Evaluation conditions

| Eriksen * | Eriksen processing after scratch test (6mm) |

|---|---|

| Winter hardiness * | Bend 180° after leaving at 0℃ for 1 hour |

| Boiling Water Test * | Soak in boiling water for 3 hours |

| Heat resistance | After leaving in a 120℃ oven for 1 hour |

* Conform to JIS standard K6744

Adhesiveness (compared to other companies' products)

Evaluation method

- Eriksen

Make a well-shaped notch in the center of the laminated steel plate with a cutter, and perform 7mm Erichsen processing from the steel plate side. - Boiling water treatment method

Erichsen processed products are treated at 100℃ for 2 hours. - Peeling method

Peel it off from the notch with tweezers.

Comparative evaluation was conducted by adding 20% Liothene and other companies' PP①~④ to epoxy adhesives for steel sheets.

| Adhesives | Resin | Eriksen | |||

|---|---|---|---|---|---|

| normal condition | Boiling water treatment after processing | ||||

| Peeling | Peeling | ||||

| Prototype A | Liothene | 5 | 5 | 5 | 5 |

| Prototype B | Competitor's product ① | 5 | 2 | 5 | 2 |

| Prototype C | Competitor's product ② | 5 | 1 | 5 | 1 |

| Prototype D | Competitor's product ③ | 5 | 1 | 5 | 1 |

| Prototype E | Competitor's product ④ | 5 | 5 | 5 | 3 |

| Structure | TPO sheet//steel plate |

|---|---|

| Coating conditions | Method: Bar coater coating NV: 23% Coating amount: 4.5g/m2dry |

| Rami conditions | Board temperature: 220℃ Lamination pressure: 5Kg/cm2 |

| Evaluation criteria | Eriksen: (Excellent) 5 No peeling ⇔ 1 Full peeling (Poor) |

Inquiries

TOYOCHEM CO., LTD. Packaging and Industrial Materials Sales Division Sales Department 1

TEL:03-3272-0940