What is an environmentally friendly roll label?

Would you like to reduce CO 2 emissions with roll labels?

- What is a roll label?

- Advantages of roll labels

- CO 2 emissions/performance comparison

- Product introduction

What is a roll label?

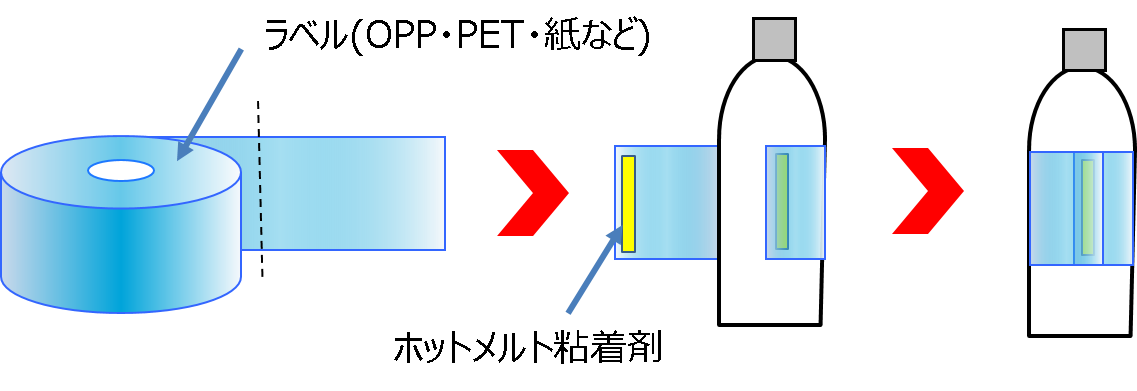

A roll label is a type of label that is coated with hot melts pressure sensitive adhesives on both ends and wrapped around a container.

hot melts pressure sensitive adhesives is melted using a special labeler and applied in-line.

Roll label products (PET bottles)

Roll label products (bottles)

Other common labels

| adhesive labels | The most common label. There are two types: solvent-based and water-based. Paste while peeling off the release paper. It can be easily applied to substrates, and the labeler is inexpensive and easy to use. |

|---|---|

| shrink labels | Used in perforated PET bottle drinks, etc. After a cylindrical label is placed on a bottle, it is heated with water vapor to shrink the label and wrap it around the container. Can be used with irregularly shaped containers and has excellent design. |

| glue label | Used on beer bottle labels, etc. A label that is attached to a paper label by applying glue dissolved in water. There is less waste and the glue is relatively inexpensive. |

Advantages of roll labels

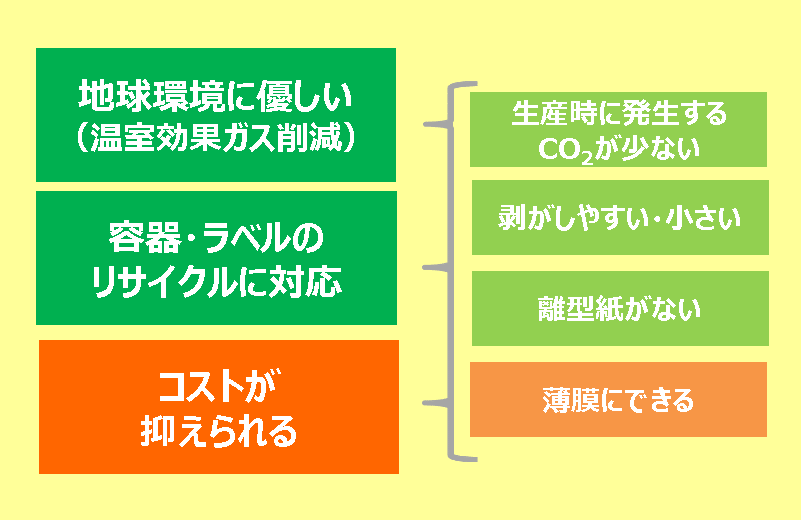

In the past, labels prioritized design as the face of the product, and were required to be large, easy to read, and not peel off from the container.

However, the functions required of labels from the perspective of global environmental conservation are changing, and roll labels have the advantage of reducing environmental impact.

New functions required for labels

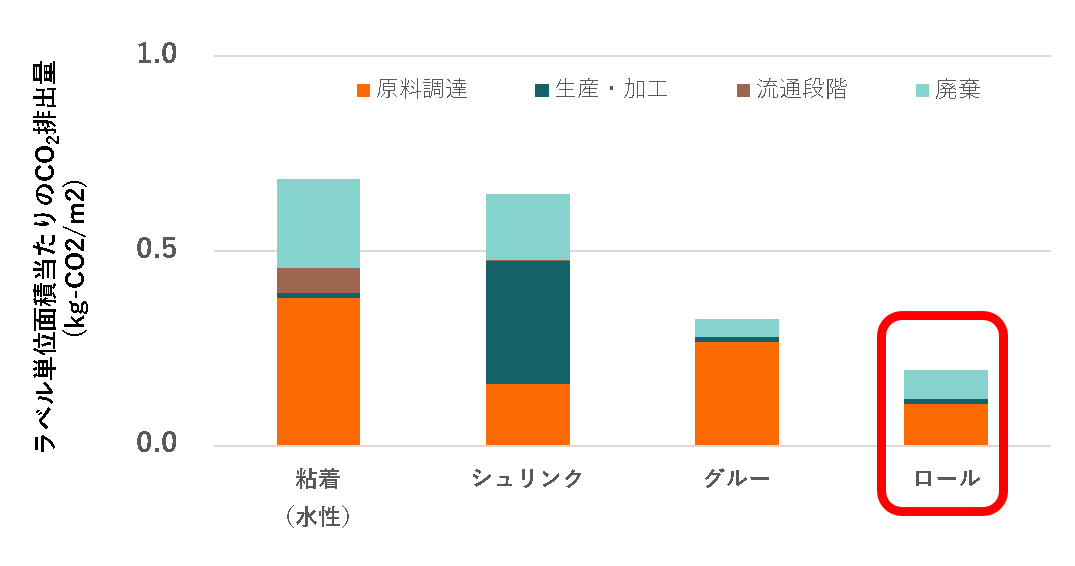

CO2 emissions and performance comparison by label

When we calculated CO 2 emissions for each type of label using CFP, we found that the CFP value for roll labels was lower than for other labels. Roll labels keep carbon dioxide emissions low by making the labels thinner and eliminating release paper.

can do.

CO2 emissions by label (CO2 emissions per unit area)

| Label | Adhesives | Others | |

|---|---|---|---|

| pressure sensitive adhesives (water-based) label |

Paper label (basis weight 85g/㎡) |

Dry: 20g/㎡ Acrylic (NV: 60%) |

Process paper (basis weight 300/m2, used 10 times) |

| shrink labels | PS40μm (shrinkage 20%) | none | Steam 470kg/hour, tunnel 5m |

| glue label | Paper label (basis weight 85g/㎡) | Dry: 20g/㎡ water-based vinyl acetate (NV: 50%) |

|

| roll label | PET label (20μm) | Application amount: 4.8g/㎡ | hot melts biomass content: 40% |

* TOYOCHEM Co., Ltd. Estimate. Assuming a label area of 20 cm × 5 cm and a production speed of 720 bpm.

What is CFP (carbon footprint)?

The amount of greenhouse gases emitted throughout the life cycle of a product or service, from procurement of raw materials to production, distribution, sales, use, disposal, and recycling, is converted into carbon dioxide and easily understood for the product or service. The display mechanism

Performance comparison by label

| adhesive labels | shrink labels | glue label | roll label | ||

|---|---|---|---|---|---|

| Environment | CFP | × | × | △ | ◎ |

| Label | lots of paper labels Base material: 85g/m2 |

Dedicated OPP/PET label Approximately 40~60μm |

paper label Base material: 85g/m2 |

Many PET/OPP labels (about 12-30μm) Paper labels also available |

|

| release paper | Yes (about 100μm) | none | none | none | |

| recycling | Alkali | × | ◎ | × | ◎ |

| Hand removability | △ | ◎ | × | ◎ | |

| cost | × | △ | △ | ◎ | |

| Production capacity | △ | 〇 | ◎ | 〇 | |

| Workability | ◎ | 〇 | × | 〇 | |

hot melts product introduction for roll labels

We have developed a hot meltspressure sensitive adhesives for roll labels " We have a lot of achievements in the LABELMELT™ series".

Our unique compounding technology and new evaluation technology have achieved both adhesive strength and easy peeling.

Click here for an introduction to the LABELMELT™ Series, a hot melts for roll labels.

Inquiries

TOYOCHEM CO., LTD. Packaging and Industrial Materials Sales Division Address Sales Department

TEL: +81-3-3272-3497