Easy-Peel Resin for Food Packaging Extrusion

TOYOMELT™ ER Series

Easy peel resin is an adhesive resin used in the lidding material of food containers such as cup noodles and yogurt. It is molded in a form that is integrated into the innermost surface of the lid material (food contact surface), and when heated, the resin melts and adheres to the container. It maintains the right adhesive strength and at the same time allows for easy and smooth removal when the lid is opened (= easy peel). In addition to the polystyrene and paper polyethylene materials that have been used in the past, food containers have also been used in recent years, such as PET resin with good gas barrier properties and environmentally friendly biodegradable resins. Based on our many years of knowledge, we have a lineup of easy-peel resins that can be applied to these materials, which are usually difficult to seal properly.

Application example

Cup noodle lid material

Yogurt lidding material

Lid Material for Retort Food

Features of our products

Achieve a smooth peeling feel

There are two main types of easy-peel resins: the interfacial peel type (peeling off at the boundary between the adhesive resin layer and the container) and the agglomeration peeling type (the adhesive resin cracks and peels off internally). A typical problem with the interface peeling type is "zipping", that is, the lid material cannot be peeled off with a certain force, resulting in a creaking sound or the contents spilling out. On the other hand, a typical defect in the agglomeration and peeling type is "stringing", that is, the adhesive resin remains like a thread on the edge of the container, resulting in a poor appearance and a risk of accidental ingestion. Our products provide a clean, smooth peeling feel with no zipping or stringing in all types.

Our easy-peel resins provide smooth peeling without these troubles

Zipping has occurred

The appearance of stringing has occurred

Uses ingredients listed in the Food Sanitation Act and the FDA's Positive List

Our Easy Peel Resin is a product made from ingredients listed in the Food Sanitation Act, Food Apparatus, Containers and Packaging Positive List, and the US FDA. The grace period of the Food Sanitation Act Positive List system has ended on May 31, 2025, and from now on, it is required to use ingredients listed on the positive list on surfaces where food comes into contact, but this product can be used with confidence.

Heat sealing at low temperatures is possible

It can heat seal at low temperatures of 120°C~.

Global Supply System

In addition to Japan, we also have production bases overseas. We can also support the overseas expansion of your business.

Featured Products

anti-fog type ER-1010

Anti-fog test results

In the case of regular easy-peel resin, water droplets stick to the lid and the contents are not visible, but in the case of this product ER-1010, water droplets do not stick to the lid and the contents can be clearly seen even after 60 minutes.

For regular Easy Peel resin (after 10 minutes)

For regular Easy Peel resin (after 60 minutes)

Anti-fog for ER-1010 (after 10 minutes)

Anti-fog for ER-1010 (after 60 minutes)

Test method: Put 100ml of water at 90°C into a container, glue the lid together with heat sealing, and let it stand in an environment of 60°C. Observe the water droplets on the lid every hour.

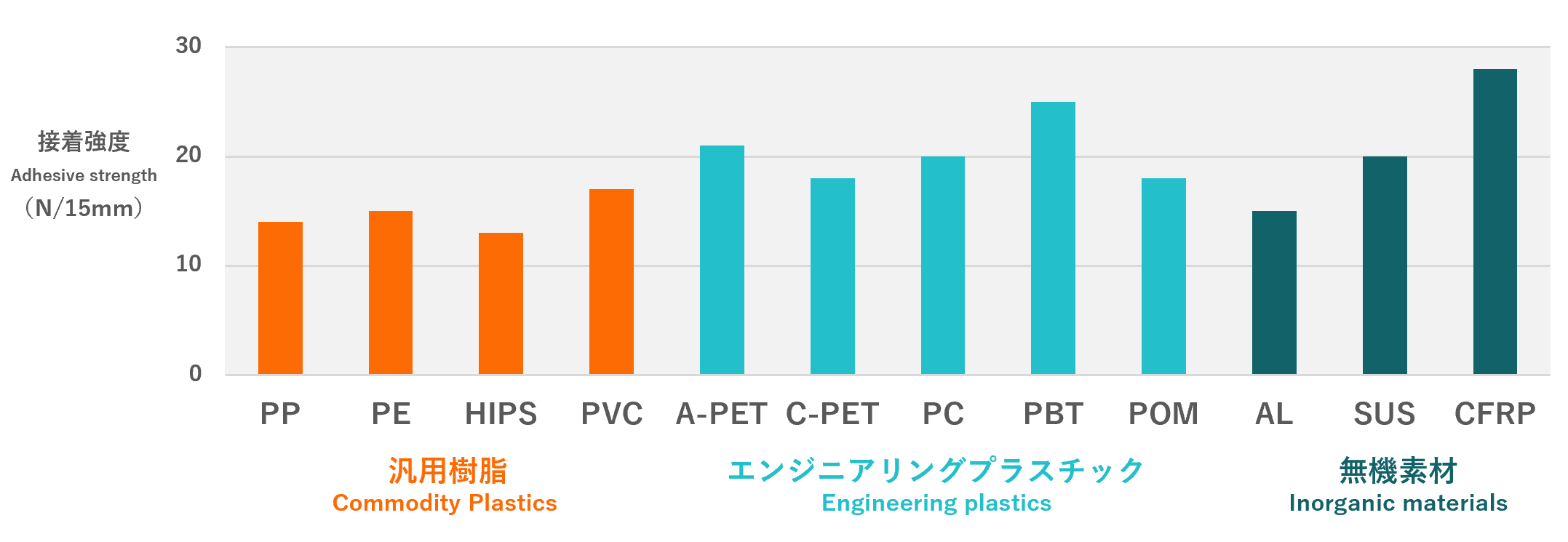

universal adhesive type ER-1009

Normally, Easy Peel resins need to be modified according to the material to be bonded, such as plastic (PE, PP, PS, PET) or metal (aluminum).

We have developed ER-1009, a general-purpose adhesive type product that can bond to a wide range of materials, including difficult-to-bond materials. This provides advantages such as bonding materials that were previously not possible, thin film by removing unnecessary layers from the lid material, and reducing the number of cleaning times of the molding machine by integrating the types of easy-peel resins used.

Main Product Lineup

There are other lineups in addition to the following part numbers. We can also customize according to customer requirements.

| Product name | forte |

MFR@190℃ (g/10min) |

Materials to be glued together | Molding method | Peeling form | ||||

|---|---|---|---|---|---|---|---|---|---|

| PE | PP | PS | PET | metal | |||||

| ER-6260H |

Easy to peel off, high seal |

21 | ✓ |

T-Die inflation Together |

Cohesive peeling | ||||

| ER-1005 |

Easy to peel off, high seal Retort, heat resistant |

9 | ✓ | ✓ | Cohesive peeling | ||||

| ER-1009 |

Easy to peel off General Purpose Adhesive |

10 | ✓ | ✓ | ✓ | ✓ | ✓ | Interface Peeling | |

| ER-1010 |

Easy to peel off Anti-fog |

10 |

✓ | ✓ | Interface Peeling | ||||

| ER-3001 |

Strong adhesion General Purpose Adhesive |

10 | ✓ | ✓ | ✓ | ✓ | ✓ | Interface Peeling | |

Inquiries

TOYOCHEM CO., LTD. Packaging and Industrial Materials Sales Division Address Sales Department

TEL: +81-3-3272-3497