What is laminating adhesives?

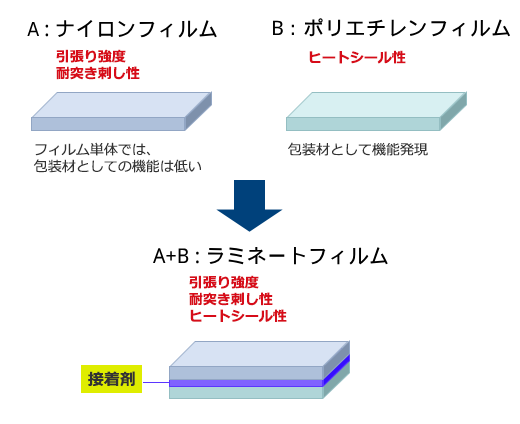

What is laminate?

What is laminating adhesives?

laminating adhesives are used to manufacture films with new functions by bonding different films together.

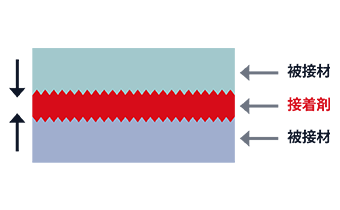

adhesives mechanism

Three effects that determine interfacial adhesion strength

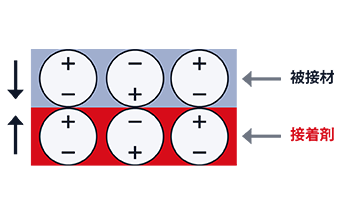

Typical coating drawing

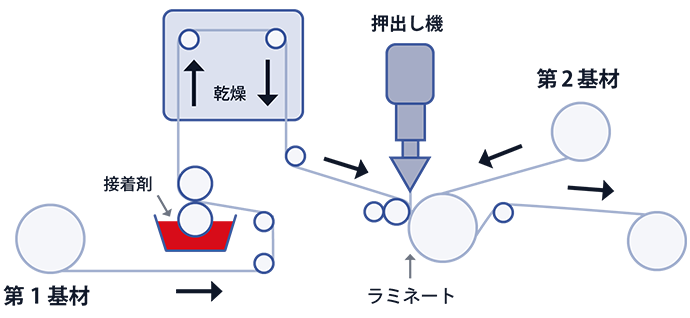

Dry laminate coating diagram

Dry lamination is a method in which a base material (film) is coated with adhesives diluted with an organic solvent, dried in a drying zone, and then bonded to another base material using heated rolls.

Features

We select adhesives that are suitable for packaging material requirements such as heat resistance and chemical resistance. This lamination method is widely used in industrial fields such as food packaging for retort foods and boiled foods, non-food packaging for detergents, and laminated steel sheets.

process

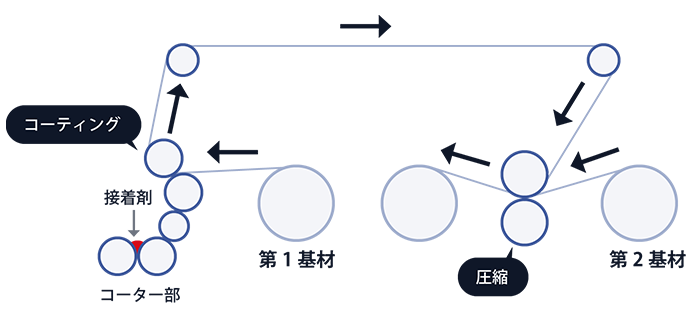

Coating diagram of solvent-free laminate

This method uses multi-stage rolls in the coater section to heat adhesives that do not use organic solvents, coat them into a thin film, and then bond them together.

Features

Since no organic solvents are used, VOC emissions are significantly reduced, making it an environmentally friendly lamination method.

It is possible to provide safe packaging materials with no residual solvent, and also contributes to improving productivity through high-speed coating.

process

Coating diagram of extruded laminate

Extrusion lamination is a method in which the first base material (film) is coated with adhesives (anchor coating agent), thermoplastic resin such as polyethylene resin is melted at high temperature, extruded into a film, and cooled at the same time as it is crimped.

Features

A laminated film with excellent flexibility and tearability is obtained, and is used for packaging liquids and granules, as well as boiled food applications such as pickles.

process

Inquiries

Toyo-Morton, Ltd.

TEL:+81-3-3272-3394