Anti-yellowing dry laminating adhesives TM-7011

This is an acrylic adhesives that is rare in the industry. It exhibits superior performance compared to urethane adhesives in terms of hydrolysis resistance, oil resistance, and yellowing resistance.

Development background

In the field of industrial materials, laminating adhesives has been increasing its need for long-term durability in harsh environments in recent years, driven by the growing demand for electric vehicles (EVs) and fuel cell vehicles (FCVs) and environmental considerations.

laminating adhesives is widely used in urethane adhesives from the perspective of ease of handling, product design freedom, and cost during production. On the other hand, in applications where long-term durability is required, hydrolysis resistance may be an issue.

We have developed an acrylic resin-based laminating adhesives "TM-7011" that has achieved a breakthrough in hydrolysis resistance by applying the acrylic resin technology of our group company TOYOCHEM CO., LTD.. Acrylic resin-based adhesives are resistant to various types of resistance but are characterized by being hard and brittle, but this product has a flexible coating design through a special formulation design.

Features

- Excellent hydrolysis resistance

- Excellent weather and heat resistance

- Excellent oil resistance

Application example

- Automotive components (insulating sheets, composite materials for gaskets, acoustics, battery surroundings, heat-resistant/durable components)

- outdoor building materials

- Electronic device related

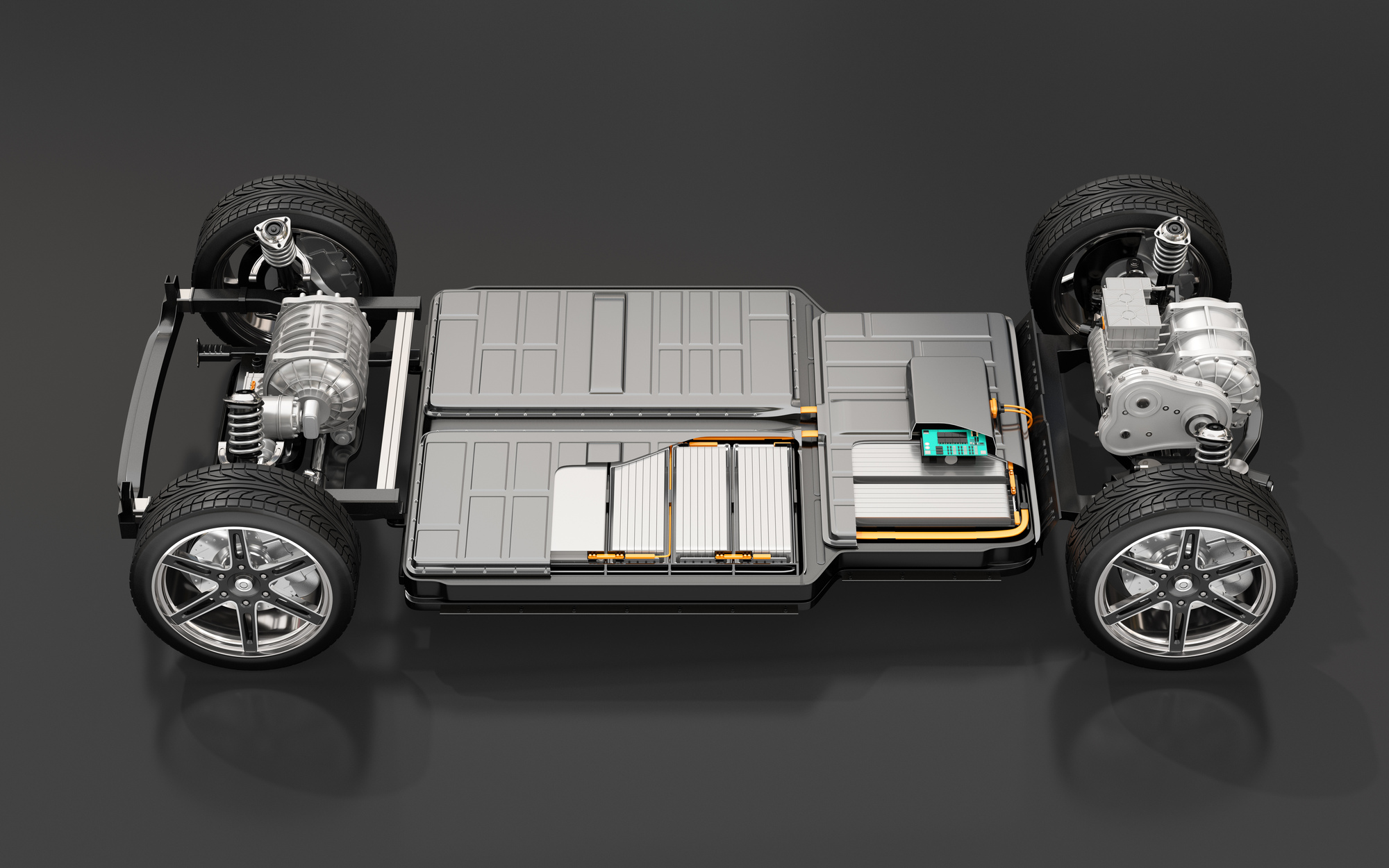

electric car motor with suspension

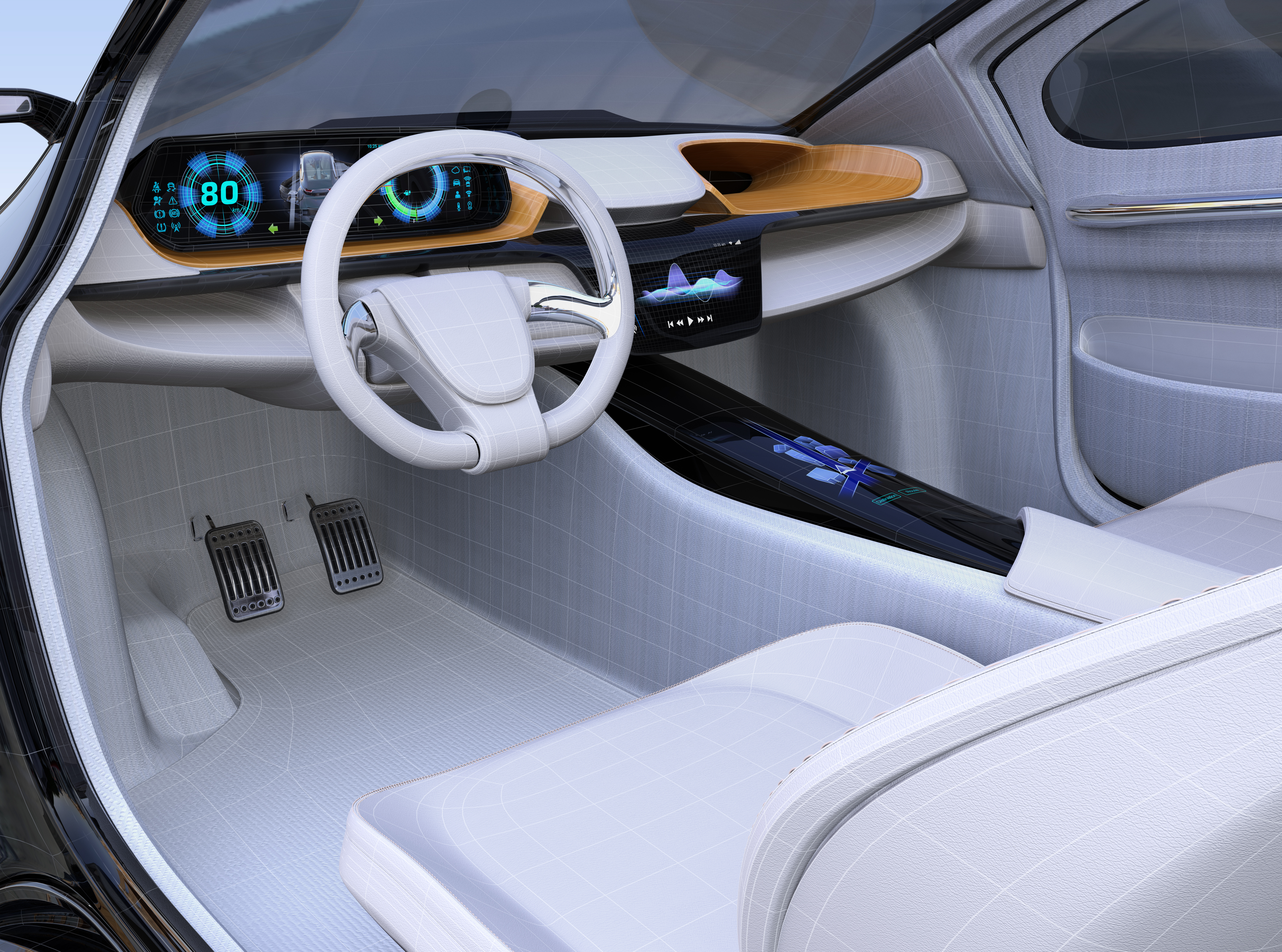

electric car interior

electric car chassis

Product Data

| Product name | Main agent | hardening agent | hardening agent |

|---|---|---|---|

| TM-7011 | LCR-1310 | LCR-1032 | |

| Appearance | transparent | light yellow transparent | light yellow transparent |

| composition | acrylic resin | isocyanate aromatic | isocyanate aliphatic |

| Non-volatile content | 50% | 52.5% | 85% |

| B type viscosity | Approximately 1,000mPa・s | Approximately 20mPa・s | Approximately 150mPa・s |

| Mixing ratio | 100 | 7 | 4 |

Physical property data

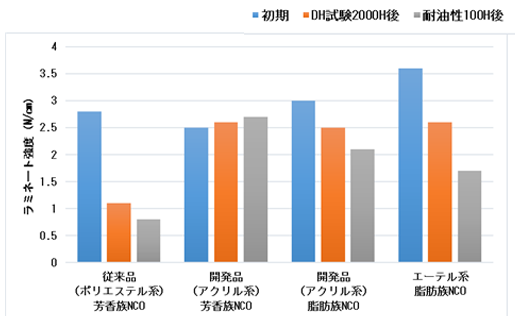

Weather resistance (moisture heat resistance)/oil resistance data

Development product (acrylic based) Aromatic NCO TM-7011/LCR-1310 = 100/7

Development product (acrylic based) Aliphatic NCO TM-7011/LCR-1032 = 100/4

* The above figures are measurements and not guarantees.

Test method

Composition: Heat-resistant base material/PET/heat-resistant base material

Processing conditions

- Application amount: 6g/㎡Dry

- Crimping temperature: 40℃

- Aging: 60℃ x 3 days

DH test: 2000 hours at 85℃85%RH

Oil resistance test

- Immersion oil: isooctane/toluene = 50/50

- Temperature over time: 80℃

- Time: 100H

- Laminate strength measurement after aging

Inquiries

Toyo-Morton, Ltd.

TEL:+81-3-3272-3394