The Polymer coating technology adds functionality to any metal and shapesHigh adhesion metal coating compatible with molding process

Product Summary

The polymer coating technology that we have cultivated can be applied to any type of metal, giving it a variety of functions such as adhesion, corrosion resistance, insulation, and heat resistance.

Applications

- Structural components for mobility

- Metal parts for electronic materials

- Steel plates for home appliances

- Building materials, etc.

Product features

KEY #1 Adding functionality to metal surfaces using polymer technology

Various surface functions such as metal adhesion, corrosion resistance, insulation, and heat resistance can be applied to various metals.

Go to detailsKEY #2 Able to coat on metals with complex structures

Add coating functionality to metals with complex and detailed structures using electrodeposition coating or spray coating.

Go to detailsKEY #3Able to transformed into any shape with high processing and highly adhesive coating

Products that can be applied to pre-coated metal can be molded even after coated.

Go to detailsspecification

KEY #1 Adding functionality to metal surfaces using polymer technology

Various surface functions such as metal adhesion, corrosion resistance, insulation, and heat resistance can be applied to various metals.

Coating properties

Coatings with a variety of properties can be created by heat curing and UV curing.

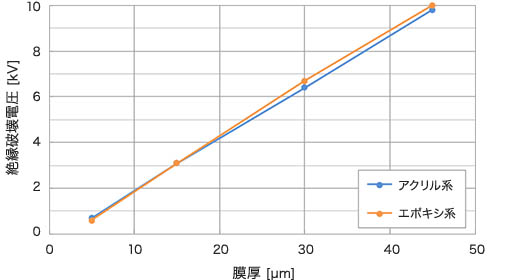

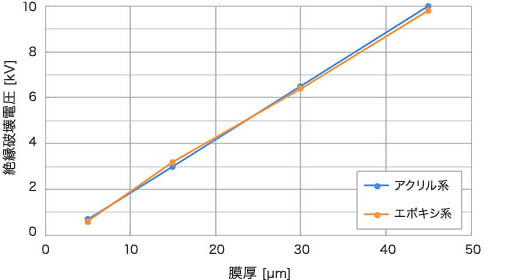

| Electrical properties | Breakdown voltage: 3kV(15μm) 6kV(30μm) 10kV(45μm) |

|---|---|

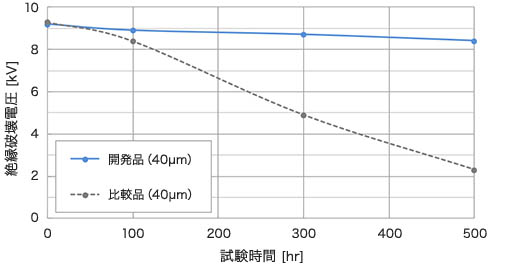

| Thermal properties | Heat resistance: Good insulation after 500 hours test at 190℃ Thermal shock resistance: Good insulation after 500 cycle tests at -40℃⇔180℃ |

| chemical properties | Neutral salt spray test (JIS H8502 7.1): No corrosion Combined cycle test (JIS 8502.8.1): No corrosion |

| Mechanical properties | Pencil hardness (JIS K 5600-5-4): 5H or more Adhesion (JIS K 5600-5-6): No peeling after cross cutting after salt spray test |

Insulation

Heat resistance

| Item | Epoxy type | ||

|---|---|---|---|

| Heat resistance | 190℃ 500 hours | Aluminum base material | No cracks etc. |

| steel base material | No cracks etc. | ||

| Thermal shock test | -40℃⇔180℃ 500 cycles | Aluminum base material | No cracks etc. |

| steel base material | No cracks etc. | ||

Corrosion resistance

| Item | Acrylic | Epoxy type | ||

|---|---|---|---|---|

| neutral salt spray test |

JIS H 8502 7.1 96 hours |

Aluminum base material | No corrosion | No corrosion |

| copper base material | No corrosion | No corrosion | ||

| combined cycle test |

JIS H 8502 8.1 30 cycles |

Aluminum base material | No corrosion | No corrosion |

| copper base material | No corrosion | No corrosion | ||

| Coolant immersion test |

90℃-1,000 hours | Aluminum base material | No corrosion | No corrosion |

| copper base material | No corrosion | No corrosion | ||

| Neutral salt spray test JIS H 8502 7.1 | |||

|---|---|---|---|

| Aluminum base material |  |

|

|

| copper base material |  |

|

|

| Unpainted | 5μm | 15μm | |

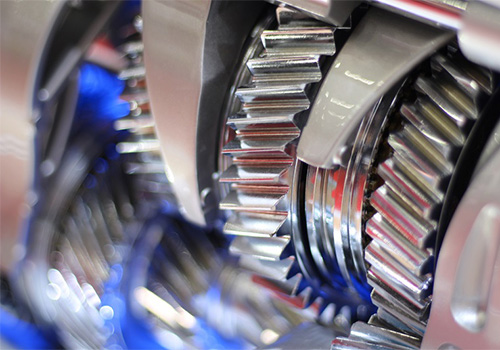

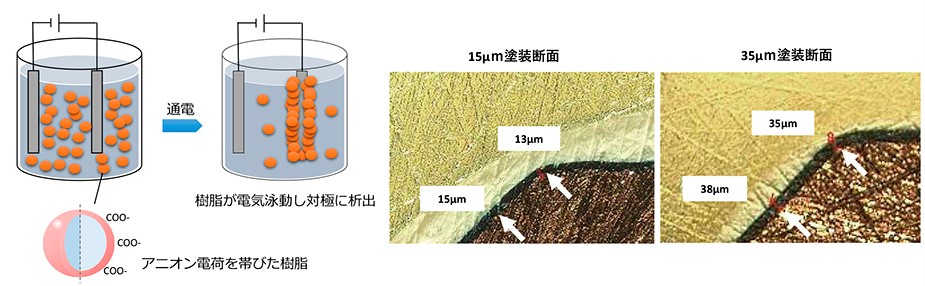

KEY #2 Able to coat on metals with complex structures

Add coating functionality to metals with complex and detailed structures using electrodeposition coating or spray coating.

Compatible with electrodeposition coating system

Achieves uniform coating with excellent edge coverage even on complex and fine metal materials.

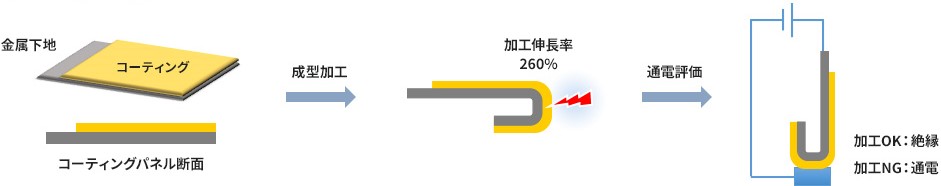

KEY #3Able to transformed into any shape with high processing and highly adhesive coating

Products that can be applied to pre-coated metal can be molded even after coated.

Compatible with pre-coated metal systems

Good coating surface quality can be obtained with natural roll coating and reverse roll coating systems.

Molding and forming ability

Excellent metal adhesion, processing followability, and hardness create a coating that can withstand complex molding processes after coated.

| Forming judgment | Processing part current | Optical microscope | Fluorescence microscope | |

|---|---|---|---|---|

| Development product | Good | insulation |  |

|

| Comparison product | defective | 66mA |  |

|

We want to aim such kind of co-creation!

What we can do for that!

A variety of functions such as metal adhesion, corrosion resistance, insulation, and hardness can be added to metal surfaces with complex shapes.

Inquiries

TOYOCHEM CO., LTD. Packaging and Industrial Materials Sales Division Sales Department 1

TEL:+81-3-3272-0856