Acrylic emulsion technology introduction

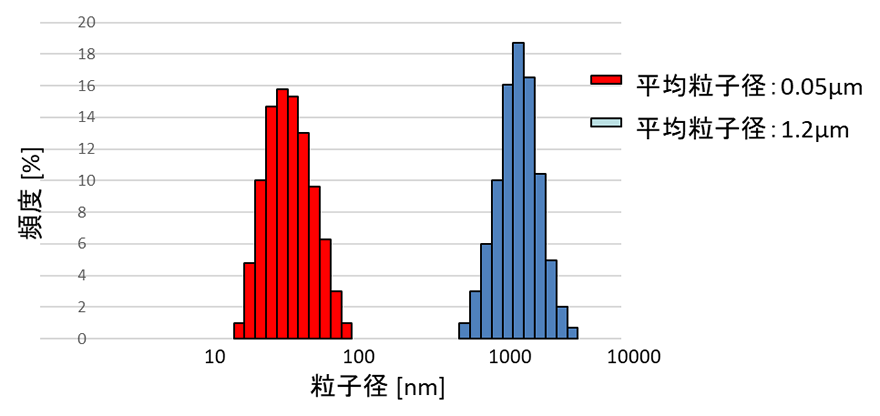

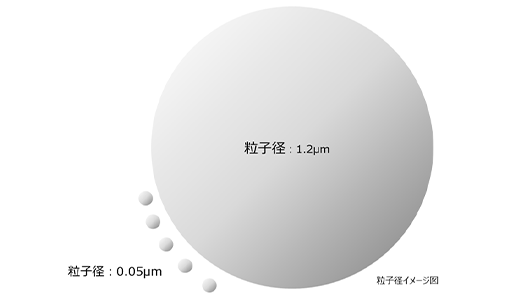

particle size control

- Resin dispersions with particle diameters of 0.02 to 10 μm can be produced.

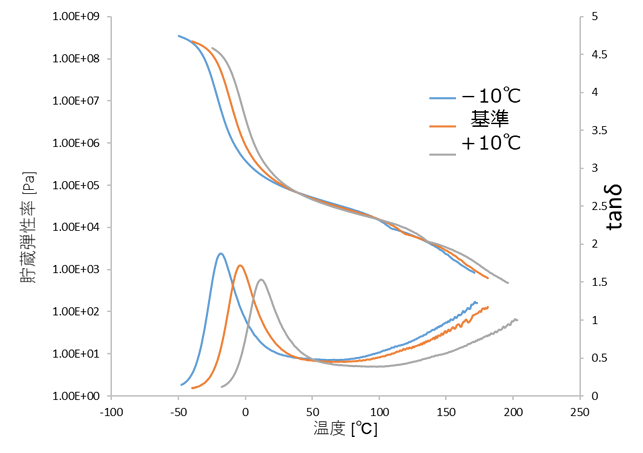

Tg control

- Optimal Tg can be adjusted by resin design.

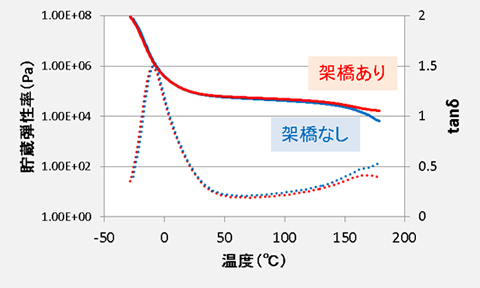

Viscoelasticity measurement results

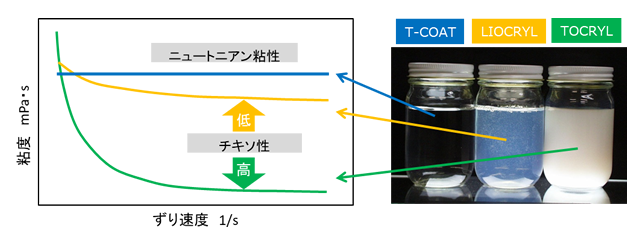

viscosity control

- Resin morphology can be controlled from soluble to heterogeneous systems.

- Viscosity can be controlled depending on the form of the resin.

core shell design

- Achieves both coating strength and flexibility.

- Film-forming properties at low temperatures can be improved.

| Calculation Tg[℃] | MFT[℃] | Strength | flexibility | |

|---|---|---|---|---|

| Normal product | 11 | 13 | ◎ | × |

| core shell design product | 11 | Below 0℃ | ○ | ○ |

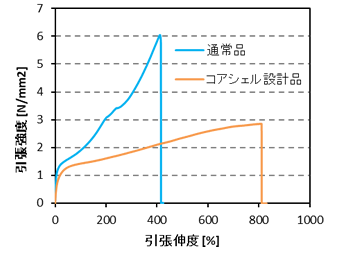

Balancing coating strength and flexibility

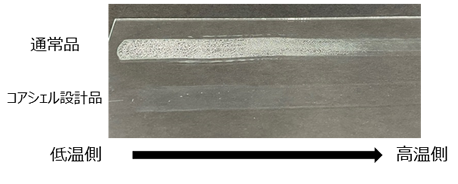

Low temperature film forming property (MFT measurement)

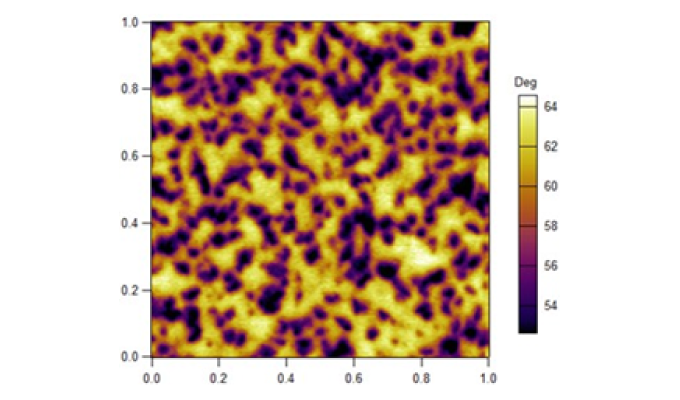

Phase separation structure of resin coating film

By controlling the phase separation structure of the resin, we not only achieve low-temperature film forming properties, but also achieve both strength and flexibility, which are often in a trade-off relationship.

crosslinking design

- Solvent resistance can be improved.

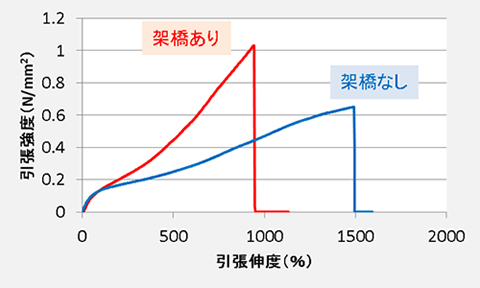

- The strength and elongation of the coating film can be controlled.

- The viscoelasticity of the coating film can be controlled.

| Solvent resistance Elution rate (%) |

Paint film strength (N/mm2) |

Coating film elongation (%) |

|

|---|---|---|---|

| No crosslinking | 50 | 1.03 | 1500 |

| With crosslinking | 90 | 0.65 | 930 |

Tensile test results

Viscoelasticity measurement results

Inquiries

TOYOCHEM CO., LTD. Packaging and Industrial Materials Sales Division Sales Department 1

TEL:03-3272-0940