REXWINR Series REXWIN UA-A2 adhesives

"REXWINR UA -A2 adhesives" is a UV curing adhesives. It exhibits excellent transparency and adhesive strength when laminated with transparent substrates (PET, acrylic, polycarbonate, glass, etc.) that transmit UV light. Ideal for bonding smartphone film modules, etc. This is a product with improved antifoaming properties of "REXWINRUA-A1 adhesives".

| Dry curing method | UV curing type | |||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Packing | 1kg | |||||||||||||||||||||||||||||||||

| Purpose/Function | Meter panel, glass, adhesive, amusement, adhesive, touch panel, metal, display, nameplate, package, card, insulation | |||||||||||||||||||||||||||||||||

| Base material | AC, PC, ABS, PVC, untreated PET, treated PET, treated PP, treated PE, painted board, paper, glass, synthetic paper | |||||||||||||||||||||||||||||||||

| Printability | Leveling property, hardening property | |||||||||||||||||||||||||||||||||

| Post-processability | Punching property | |||||||||||||||||||||||||||||||||

| Paint film appearance | Transparent, non-yellowing | |||||||||||||||||||||||||||||||||

| Paint film properties | adhesiveness, tackiness | |||||||||||||||||||||||||||||||||

| Electrical properties | Insulation | |||||||||||||||||||||||||||||||||

| Characteristics (other) |

|

|||||||||||||||||||||||||||||||||

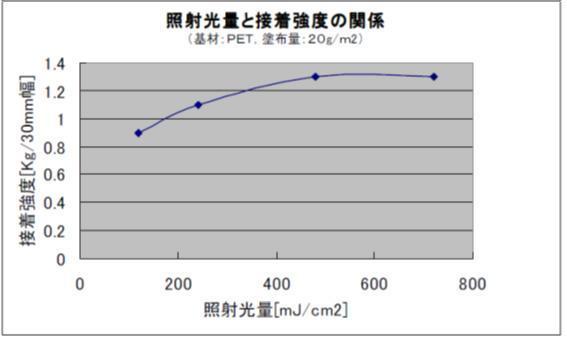

| UV硬化条件 |

Approximately 480mJ/c㎡ |

|||||||||||||||||||||||||||||||||

| Auxiliary agents, additives, cleaning solvents, etc. |

SS Plate Cleaner ECO Series...A plate cleaning agent for screen printing that does not fall under organic regulations or the PRTR law. SD is the standard type, and QD is even faster drying. |

|||||||||||||||||||||||||||||||||

| Printing conditions |

Screen printing (100-150 mesh, etc.), dispenser coating * Viscosity: 40±10 dPa·S/25°C |

|||||||||||||||||||||||||||||||||

| How to use ink & precautions |

If viscosity adjustment is required, please use "FDSS3 Regiuser" (addition amount 5% or less). |

|||||||||||||||||||||||||||||||||

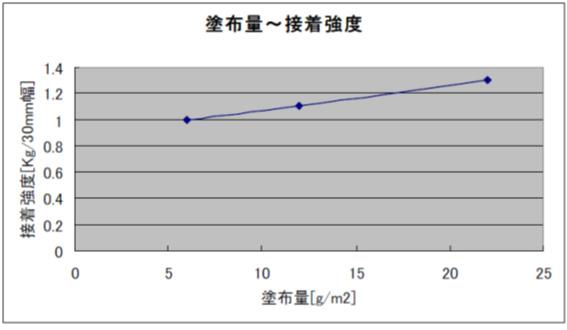

| Physical properties |

Composition: PET/PET (100μm)

* 1: Configurations are tested by PET/ adhesives. |

|||||||||||||||||||||||||||||||||

| Requests for use |

|

Inquiries

TOYO INK CO., LTD. Marketing Division Business Planning Department

TEL:03-3272-7693