LIOCREATE® ™ SSPO Series SS PO Series

It has excellent adhesion and physical properties to treated polyethylene, treated polypropylene, treated polyester, etc. This is a two-component reactive screen ink that is especially suitable for reproducing fine text on plastic bottles.

| Dry curing method | 2-component curing type | ||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Packing | 1kg | ||||||||||||||||||||||||||||||

| Purpose/Function | Tubes, bottles, stickers, meter panels, glass, amusement, metal, displays, nameplates, packages, cards, plastic moldings, insulation | ||||||||||||||||||||||||||||||

| Base material | PC, ABS, PVC, untreated PET, treated PET, treated PP, treated PE, painted board, paper, synthetic paper | ||||||||||||||||||||||||||||||

| Printability | Leveling properties, curing properties, high speed printing properties | ||||||||||||||||||||||||||||||

| Post-processability | Recoatability, punchability | ||||||||||||||||||||||||||||||

| Resistance | Heat resistance, hot water-based resistance, weather resistance | ||||||||||||||||||||||||||||||

| Paint film strength | Tough coating, flexibility | ||||||||||||||||||||||||||||||

| Chemical Resistance | Acid resistance, alkali resistance, alcohol resistance, oil resistance, gasoline resistance, sunscreen resistance | ||||||||||||||||||||||||||||||

| Electrical properties | Insulation | ||||||||||||||||||||||||||||||

| Characteristics (other) |

|

||||||||||||||||||||||||||||||

| Finish, texture, appearance effect | Semi-gloss (semi-gloss) | ||||||||||||||||||||||||||||||

| setting color | 121M red, 141 red, 151 red, 132 red, 171 red, 182 red, 193M red, 516 vermillion, 529 vermilion A, 219 yellow, 221 yellow, 221M yellow, 222 yellow, 232 yellow, 262M yellow, 263 yellow, 037 Indigo, 391 Indigo, 791 Grass B, 821 Purple, 871 Brown, 611 White, 911 Sumi, Medium | ||||||||||||||||||||||||||||||

| diluting solvent |

|

||||||||||||||||||||||||||||||

| Heat dry curing conditions | 80-90℃×5 minutes | ||||||||||||||||||||||||||||||

| Auxiliary agents, additives, cleaning solvents, etc. | SS Plate Cleaner ECO Series...A plate cleaning agent for screen printing that does not fall under organic regulations or the PRTR law. SD is the standard type, and QD is even faster drying. | ||||||||||||||||||||||||||||||

| How to use ink & precautions |

|

||||||||||||||||||||||||||||||

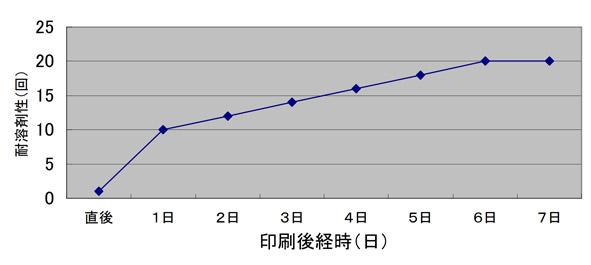

| Physical properties | Test piece: treated polyethylene bottle (520μN/cm) Test ink: SS PO911 Sumi + SS UR110B additive (10%) Screen: 270 mesh (nylon) Drying: 90℃ x 5 minutes

|

||||||||||||||||||||||||||||||

| Solvents | Ethyl acetate resistance (number of times) |

||||||||||||||||||||||||||||||

| Requests for use |

|

Inquiries

TOYO INK CO., LTD. Marketing Division Business Planning Department

TEL:03-3272-7693