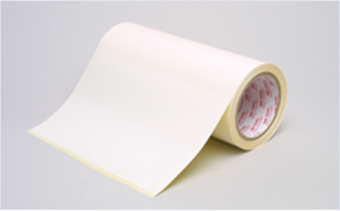

Anti-tracking tape

This is an insulating tape for next-generation EVs that uses our proprietary resin synthesis technology and coatings technology. It is the first in the industry to achieve both heat resistance (RTI 180°C) and tracking resistance (1000V * 1) (* 2). It is also durable for the reflow process. It can be used as an insulating material for enclosures such as transformers/reactors, inverters, and junction boxes for EV components.

* 1 According to our test method

* 2 According to our research

* 1 According to our test method

* 2 According to our research

forte

- Achievement of tracking resistance of 1000 V * Based on our test method

- Heat resistance equivalent to RTI180℃

- Breakdown voltage 5.0KV

- Less stringing of pressure sensitive adhesives can solve problems such as glue returning after processing, glue flying, and dust adhering to the adhesive end surface.

It has higher adhesive strength than conventional double-sided tapes and exhibits stable performance over a wide temperature range.

Application

- Insulating tape for transformers/reactors for EV applications

- Insulating materials for the housings of high voltage junction boxes, inverters, etc.

Product Data

| Product number | Thickness | Breakdown voltage (AC60Hz) | 耐トラッキング性(UL746) | Tracking resistance (our test method) | Flame retardant (UL510FR) | Temperature rating (UL-Performance test) |

|---|---|---|---|---|---|---|

| LIOELM ™ LE100 |

85μm | 5.0kV | >600V | >1000V | Passed | 180℃ |

Tracking Resistance Test at 1000V

Conventional tape

Our anti-tracking tape

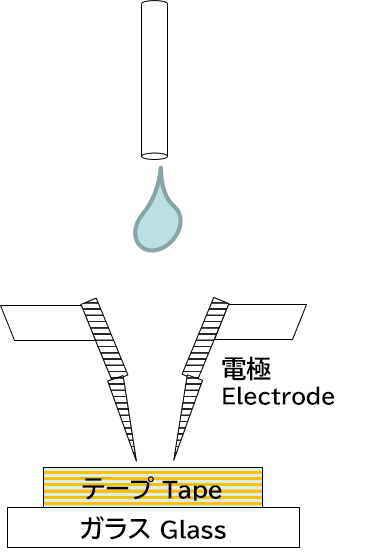

(Reference) Our Tracking Resistance Test Method

| Test circuit | Test voltage | 100~1000V (sine wave voltage) |

|---|---|---|

| Short-circuit current | Automatically stops when current of 0.5A or more flows for 2 seconds | |

| Electrode | Material, size | The tip is platinum, width 5mm, thickness 2m, tip angle 30° only. |

| Electrode mounting angle | 60° | |

| Interelectrode distance | 4.0±0.1mm | |

| Electrode load | 1±0.05N | |

| Dripping device | Dripping interval | 30±5 seconds |

| Dripping port height | 30~40mm | |

| Electrolyte | Solution A | Ammonium chloride 0.1±0.002% aqueous solution, resistivity 3.85±0.05Ω・m |

Notes in Use

- Clean the adherend (Remove dust, any other foreign particles, water, and oil.)

- Make sure that the adherend is free of burrs and warpage.

- Apply the tape to the adherend at a temperature of around 20 degrees centigrade wherever possible.

- After applying the tape, press firmly.

- Be sure to conduct a test before using the tape to check that the tape is suited for the application.

- These tapes are for industrial use only. Do not use them for the following applications.

・Applications that involve or may involve the direct attachment of the tape to the skin.

・Applications that involve the direct attachment of the tape to food.

Notes on strage

- Store the product in a room away from sunlight. Keep it away from high temperatures and humidity. (The desirable temperature is 5 to 40 degrees centigrade, and the desirable humidity is 60% or lower.)

- Avoid placing the product directly on the ground or floor. Place it on a table that allows air to pass through.

- When storing tapes in a stack, be sure to insert a removable material, such as inserting paper, between the tapes and stack them vertically.

Featured Products

Inquiries

TOYOCHEM CO., LTD. Information and Communication Materials Sales Division

TEL:+81-3-3272-0930