Creating new value with customersThe story behind the development of foaming coating for draft beer can

In 2021, Toyochem Co., Ltd. and ASAHI BREWERIES worked on the development of a "foaming can" for draft beer cans released by ASAHI BREWERIES, LTD.

"Draft Beer Cans" have become a hot topic as they allow you to experience the excitement of a delicious draft beer just by opening the lid of the beer can, which you can enjoy anywhere in the store.

Using our key technology, we would like to introduce our "Beer Foaming can coatings" which we jointly developed with ASAHI BREWERIES, by challenging overturn conventional wisdom, and its mechanism.

- Was can coatings foaming beer cans actually a failure?!

- Creating new value through co-creation with customers

- The secret to foaming with can coatings

- Co-creation with customers

Was can coatings foaming beer cans actually a failure?!

The interior coating of beer cans is used to protect contents (beer) and it was common sence that the cans would not explode when opened. Despite this, one day the coating we developed caused a large amount of explosion, and according to industry standards, it was a total failure product that was completely unusable.

Properties of Metal coating① Corrosion prevention

Protect cans from contents (beer)

Properties of Metal coating② Keep the delicious taste

Prevents the metallic components of the can from dissolving into the contents (beer) and changing the flavor.

Common sense: Beer should not foam (explode) when you open the can.

Foaming = defective product that stains consumers' clothes and homes

Big failure

When developing a coating for regular beer, by using a special material caused the beer to foam (failure).

Beer filling, can opening test (immediately after opening)

Cans coated with regular coating

Cans coated with failed coating

Creating new value through co-creation with customers

The customer's desire to create a new type of beer can that is not bound by conventional wisdom combined with our technological knowledge led to the creation of new value.

| accumulated can coatings technology |

|---|

|

+

| With Asahi Breweries partnership |

|---|

|

Converting past failures into value = creating new value

The secret to foaming with can coatings

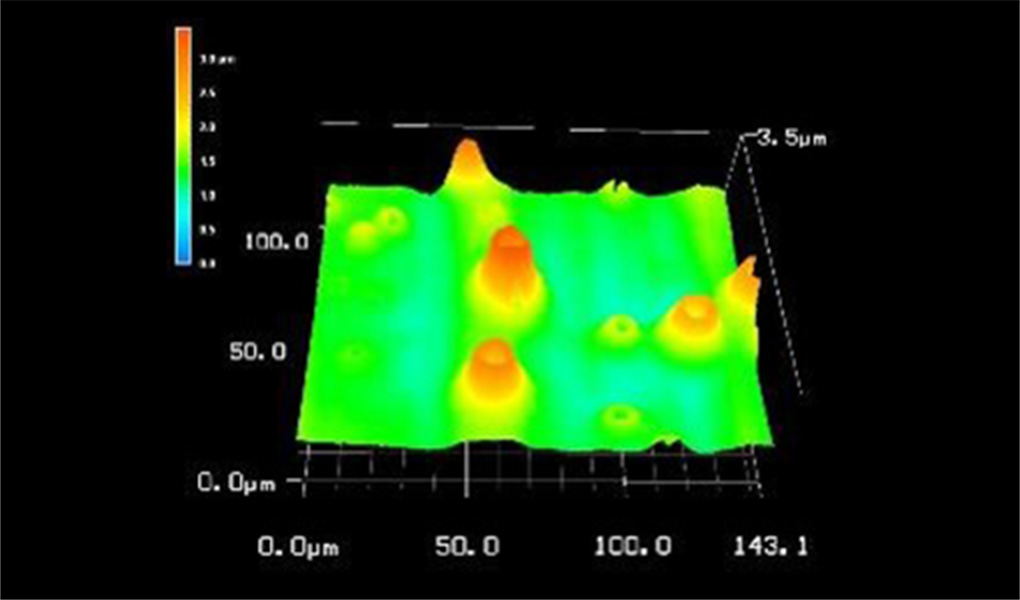

The use of special materials creates characteristic unevenness on the inside of the can.

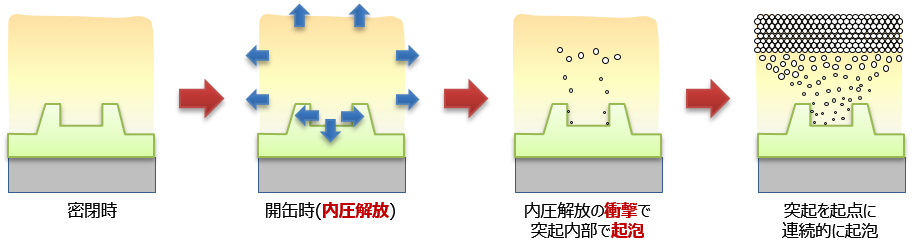

As a result of research and development with Asahi Breweries, we discovered that the natural foaming caused by the release of internal pressure when the lid is opened is amplified by this uneven structure, which is related to the foaming of beer.

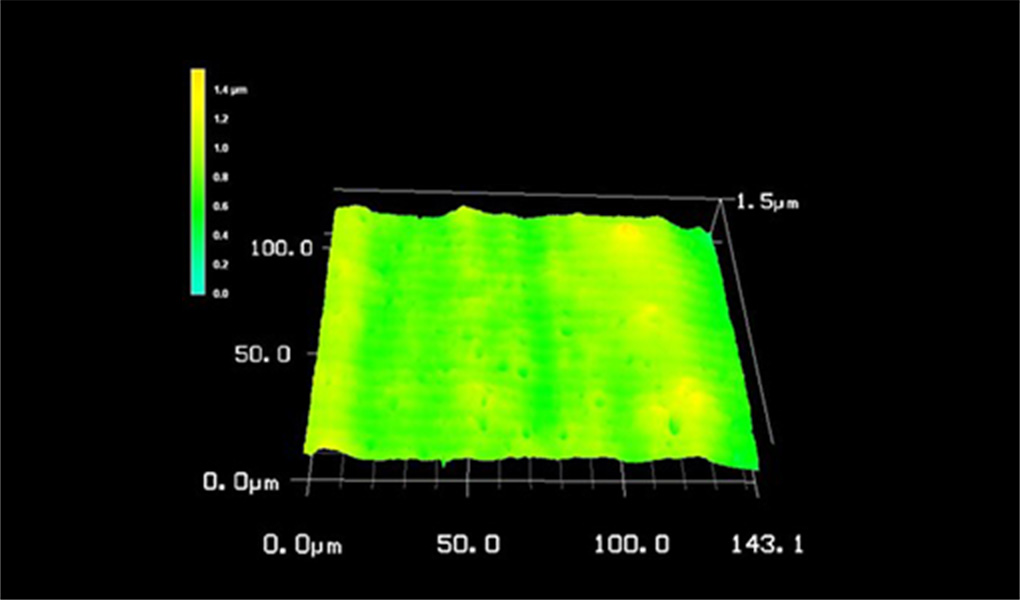

①Confocal laser microscope observation image

Inside of a can coated with regular coating

Inside of a can coated with foaming coating

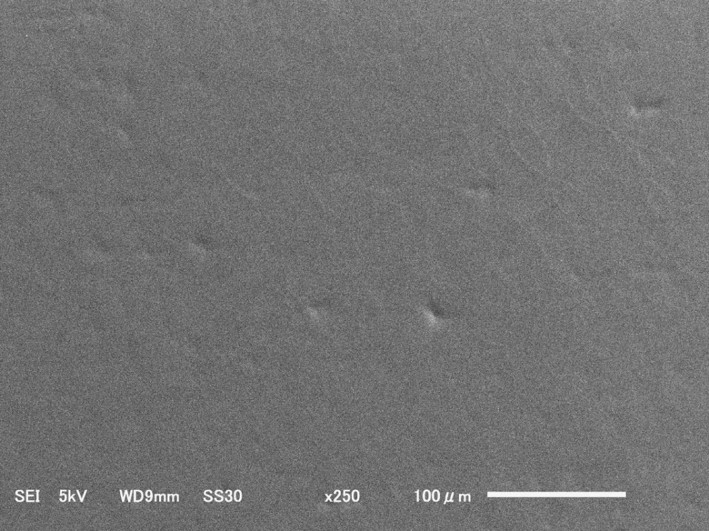

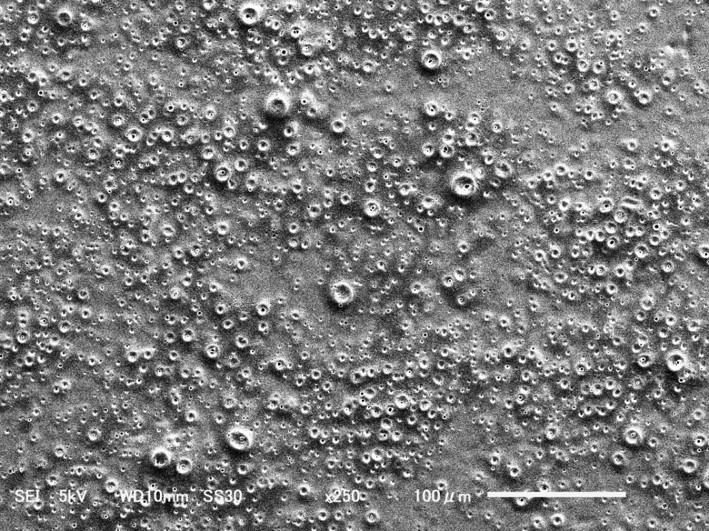

②Electron microscope observation image

It can be observed that crater-like irregularities are formed.

Inside of Asahi Super Dry regular can

Inside of Asahi Super Dry “Draft beer can”

③Predictable mechanism of beer foaming

Beer foaming test

Comparison of foaming when coated metal plates are immersed in beer

View High adhesion metal coating compatible with molding process

Co-creation with customers

Customer's voice

Usually, the development of beverage cans was carried out only with the can manufacturer.

Normally, when it comes to internal coating properties, we are indirectly involved through the can manufacturer, so it was an unusual case that we worked directly with Can coating manufacturer TOYOCHEM.

Our joint development was a combination of various coincidences, but looking back, I feel that it was a very fruitful project.

TOYOCHEM was quick to respond, willingly accommodating requests for improvements just before testing the actual machine, and had a wealth of scientific knowledge, making for a truly fulfilling technical exchange.

ASAHI BREWERIES, which has delivered deliciousness that exceeds expectations to customers through two approaches: evolving the contents of the beverage and its aluminum packaging aluminum. From this co-development, we have acquired a new approach called interior coating. By continuing to refine this partnership, we hope to deliver even more "delicious!"

In conclusion

Throughout our many years of product manufacturing, we have taken each and every success, both successful and unsuccessful, seriously and have accumulated technology. This time, we were able to sincerely address the needs of customers with different perspectives and create unprecedented value. Through co-creation with our customers, we will continue to provide new value that enriches the lives of people around the world.

(Excerpted and reorganized from the integrated report issued by our group in July 2022)

Inquiries

TOYOCHEM CO., LTD. Packaging and Industrial Materials Sales Division Sales Department 1

TEL:+81-3-3272-0856