Environmentally Friendly Products / Utilization of Life Cycle Assessment

Basic approach

We believe that it is important to reduce the environmental impact of our products for environmental conservation, and we have established the "Basic Policy on the Environment" (revised in January 2024) and have been working to provide environmentally friendly products and services "environmentally-friendly Product *" from an early stage. In order to promote initiatives such as environmental conservation and sustainable raw material procurement, we aim to reduce the environmental impact of the entire life cycle, including raw material procurement, production, use, disposal, and recycling, and promote manufacturing using LCA (Life Cycle Assessment).

- In January 2022, we defined "sustainability-contributing products" by adding "environmental value," which aims to realize a society that coexists with the environment, and "life value," which aims to realize a comfortable, healthy, and safe society. Traditional environmentally-friendly products are included in the "environmental value".

Targets and achievements

Targets

Achievements

| KPIs and Measures | FY2024 Results |

|---|---|

| Expanding the lineup of sustainability-contributing products (environmental value products) |

|

| Establishment of our own CFP calculation system based on international rules and application to specific product fields |

|

- The following page introduces information related to the "environment", such as a list of environmentally-friendly products provided by artience group and environmental marks.

environmentally-friendly Products

Utilization of LCA

The Group is working to visualize its environmental impact using Life Cycle Assessment (LCA), which is a method for quantitatively assessing the environmental impact of a product's life cycle, including raw material procurement, production, use, disposal, and recycling.

In response to the growing demand for disclosure of greenhouse gas (GHG) emissions from Europe and other industries in recent years, we are building an initiative system that includes the formulation of rules for calculating greenhouse gas emissions (carbon footprint, CFP) for each product and the development of a system in order to provide the value of low-carbon and decarbonized products that solve climate change issues.

At present, we are using the average GHG emission factors that are publicly available, but we will promote cooperation and collaboration with the supply chain to utilize the actual emission factors, which will lead to the design, development, and provision of products that take into account lower carbons.

Examples of initiatives

- Development of human resources who have acquired SuMPO Certified LCA Experts

- Establishment of a CFP Initiative System for Each Product

- Promoting low-carbon value in the product development phase and business exploration (e.g., deinking)

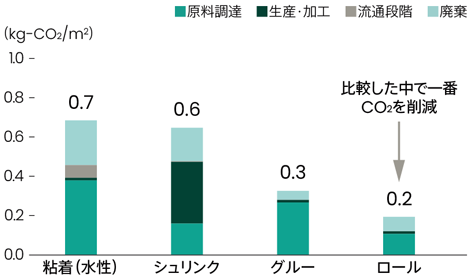

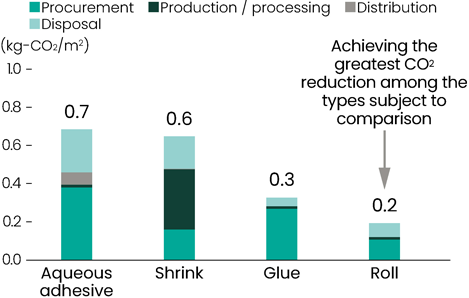

Further reduction of environmental impact by expanding the use of environmentally friendly pressure sensitive adhesives (hot melts for roll labels)

The hot melts pressure sensitive adhesives for roll labels, which are often used in PET bottled beverages, can be easily peeled off, and even if the label is still attached, it can be separated by the alkaline peeling property of pressure sensitive adhesives, making it easy to separate and contribute to the efficiency of recycling. In addition, by reducing the amount of material used as much as possible by making the label base material thinner and partially coating the pressure sensitive adhesives, it is possible to reduce the environmental impact (CO2 emissions) compared to other label systems. TOYOCHEM Co., Ltd. is developing new products for hot beverage bottles in vending machines and proposing non-beverage containers such as daily necessities and seasonings with the aim of further expanding the use of roll labels, and will continue to focus on initiatives aimed at contributing to a recycling-oriented society.

Mr. Miyazaki(left) and Mr. Suzuki(right) of TOYOCHEM Co., Ltd.

Ms. Arai of Toyochem CO., Ltd.

* Figures are calculated in-house and have not been verified by a third party

Commitment to ISCC PLUS

artience group promotes the development and launch of products and services that meet the needs of society and customers, and strives to provide products and services that contribute to the realization of a sustainable society.

In order to strengthen the handling of environmentally friendly products, the TOYOCHEM CO., LTD. Kawagoe Plant (Kawagoe City, Saitama Prefecture) has acquired ISCC PLUS certification (* 1), one of the international certification systems for sustainable products. We express our commitment in the following declaration.

"TOYOCHEM CO., LTD. is committed and declares that it will comply with the ISCC PLUS requirements in accordance with the latest ISCC regulations when handling sustainable products made from biomass raw materials and recycled raw materials produced using the mass balance method (* 2)."

* 1 ISCC PLUS Certification: This certification system is developed by ISCC (International Sustainability and Carbon Certification). Products made from raw materials derived from renewable resources such as biomass and raw materials derived from recycled resources, such as recycled resins, are examined to ensure compliance with requirements for traceability throughout the supply chain.

* 2 Mass balance method: When a raw material with a certain characteristic (e.g., a raw material derived from renewable resources such as biomass) is mixed with a raw material that does not have a certain characteristic (e.g., a raw material derived from petroleum) in the processing and distribution process from raw materials to a product, the characteristic is assigned to a part of the product according to the input amount of the raw material with that characteristic.

TOYOCHEM CO., LTD.

President and Representative Director

Yasushi Ariyoshi