Waste Management

Basic approach

artience group is a manufacturing enterprise, and the generation of waste in its production activities is inevitable. We are working to minimize the amount of waste generated by developing production processes that are less likely to generate waste, considering waste disposal methods, promoting resource recycling such as reuse and recycling, and sharing know-how on waste reduction globally. In addition, while waste oil, waste plastics, and wastewater account for about 80% of Japan's external waste emissions, we are working to minimize the amount of landfill by effectively using waste plastics that are dirty and difficult to recycle (including heat recovery).

- Amount of waste discharged externally: The amount of waste sold as valuable materials and waste generated within the business site that is not recycled within the site or discharged outside the business site to be entrusted with disposal to a waste disposal company. amount moved to

Targets and achievements

Targets

Achievements

The final amount of waste disposal is defined as the amount of waste to be disposed of before the volume reduction, such as incineration, and "zero emissions" is defined as "the final disposal amount (final disposal rate) of 1% or less of the amount of waste generated".

In FY2024, the final disposal rate for the total amount of waste generated in Japan was 0.1%, and all business sites achieved zero emissions. We will continue to promote zero emissions overseas.

| 2022 | 2023 | 2024 | FY2030 (Target) |

|---|---|---|---|

| Domestic: Achievement | Domestic: Achievement | Domestic: Achievement | Achieving zero emissions (total waste disposal rate of 1% or less at Group sites) through the promotion of 3Rs throughout production activities |

| 2020 | 2021 | 2022 | 2023 | 2024 | |

|---|---|---|---|---|---|

| Domestic | 0.0 | 0.0 | 0.0 | 0.2 | 0.1 |

| Group (Domestic and Overseas) | ー | ー | ー | ー | 1.6 |

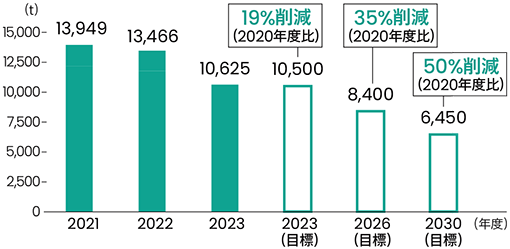

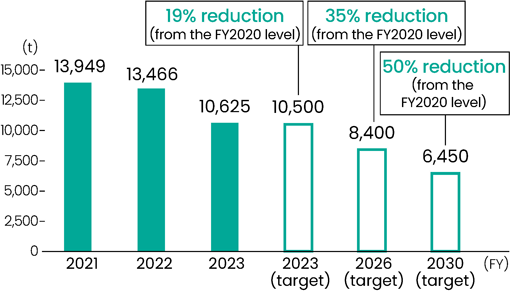

Waste generation

In FY2024, waste generation was 14,613 tons in Japan (up 3.6% from the previous year) and 13,186 tons overseas (up 6.8% from the previous year).

Based on the Ministry of the Environment's "Manual for Formulating Industrial Waste Treatment Plans by Large Emission Companies," domestic business sites aggregate the amount of industrial waste that is outsourced to contractors for disposal (waste for which a manifest is issued at the time of outsourcing), as well as the amount of waste before intermediate treatment, including valuable items and in-house reuse.

Scope of aggregation: Major domestic factories and domestic affiliated companies, overseas includes major overseas production affiliates

- In fiscal 2022, the figures for Kansai Branch (Neyagawa), Kansai Branch (Toyama), Chubu Branch (Kasugai), TOYO INK Hokkaido Co., Ltd., TOYO INK Chugoku and Shikoku Co., Ltd. (Okayama), TOYO INK Chugoku and Shikoku Co., Ltd. (Takamatsu), and TOYO INK Kyushu Co., Ltd. (Fukuoka) are included in domestic affiliates.

- In FY2023, there was a consolidation and abolition of organizations at TOYO INK Co., Ltd., but the scope of aggregation remains unchanged from FY2022

- Reduction of waste solvents by introducing a solvent recycling system

- Education on proper waste management

Efforts to reduce industrial waste ~Succeeded in making sludge valuable by introducing sludge volume reduction equipment~

TOYO FPP Co., Ltd. (Kawaguchi) is developing a business centered on the manufacture of cylinder plates and flexo plates, and wastewater treatment is essential in the process of plate making. Sludge is generated during the wastewater treatment process at the site, and until now, it was necessary to treat it as industrial waste, and cost reduction was an issue.

On the other hand, the Sustainability Vision ASV2050/2030 sets out to achieve zero emissions throughout the Group and promote resource conservation and resource recycling by 2030.

As an activity to achieve the target, we considered reducing the volume of sludge generated by about 45 tons per year, and by introducing a regenerative drying equipment, we were able to reduce the total amount of industrial waste generated by TOYO FPP Co., Ltd. by approximately 20%. In addition to reducing transportation costs, by finding a material recycling source for the metal components contained in sludge, it is possible to recycle it as a valuable material.

As a result, the amount of industrial sludge generated in the wastewater treatment process is virtually zero.

May 16, 2023 Examination of optimization conditions after introduction